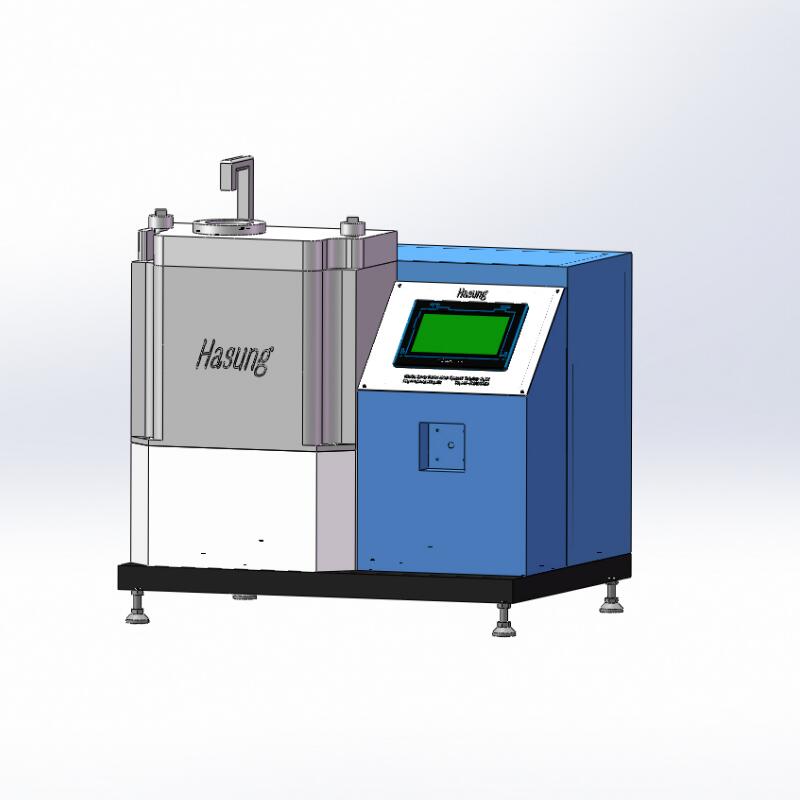

4 Bars 1kg Automatic Gold Bar Ho Etsa Machine Hasung

Tekheniki Parameters

| Mohlala No. | HS-GV4 | HS-GV15 | HS-GV30 | ||

| Mochine oa ho Bula ka Othomathike oa Khauta Bar Vacuum Casting Machine | |||||

| Phepelo ea motlakase | 380V ,50/60Hz | ||||

| Kenyeletso ya Matla | 50KW | 60KW | 70KW | ||

| Max Temp | 1500°C | ||||

| Kakaretso ea Nako ea ho Lahlela | 10-12mins. | 12-15mins. | 15-20mins. | ||

| Tšireletso ea Khase | Argon / naetrojene | ||||

| Lenaneo la li-bar tse fapaneng | E fumaneha | ||||

| Bokhoni | 4kg: 4pcs 1kg, 8pcs 0.5kg kapa ho feta. | 15kg: 1pcs 15kg, kapa 5pcs 2kg kapa ho feta | 30kg: 1pcs 30kg, kapa 2pcs 15kg kapa ho feta | ||

| Kopo | Khauta, Silver, Platinum, Palladium (Ha ka Pt, Pd, customized) | ||||

| Pumpu ea Vacuum | Pompo ea vacuum ea boleng bo holimo (e kenyelelitsoe) | ||||

| Mokhoa oa ts'ebetso | Ts'ebetso ea senotlolo se le seng ho phethela ts'ebetso eohle, sistimi e se nang kelello ea POKA YOKE | ||||

| Tsamaiso ea taolo | 10" Weinview / Siemens PLC +Sistimi e bohlale ea ho laola mochini oa motho (ho ikhethela) | ||||

| Mofuta o phodileng | Sehatsetsi (se rekisoang ka thoko) kapa Metsi a mathang | ||||

| Litekanyo | 1460*720*1010mm | 1460*720*1010mm | 1530x730x1150mm | ||

| Boima ba 'mele | 300KG | 300KG | 400KG | ||

Selelekela sa Mochini oa Hasung Gold Bar Vacuum Casting - The Ultimate Solution bakeng sa Libara tsa Khauta tsa boleng bo holimo le tsa silevera.

Na u batla litharollo tse tšepahalang, tse sebetsang hantle bakeng sa ho hlahisa libara tsa boleng bo holimo tsa khauta le silevera? Khauta bar vacuum lahla mochine ke khetho ea hao molemo ka ho fetisisa. Thepa ena ea morao-rao e etselitsoe ho finyella litlhoko tsa ba qalang le litsebi tse nang le phihlelo indastering ea tšepe ea bohlokoa. Ka ts'ebetso ea eona e ikemetseng ka botlalo le bokhoni ba ho qhibiliha ka potlako, mochini ona ke khetho e phethahetseng bakeng sa ba batlang liphetho tse ntle ka boiketlo le ka nepo.

Mechini ea ho akhela bareng ea khauta e entsoe ka theknoloji ea morao-rao ho fana ka boiphihlelo bo bonolo le bo bonolo ba basebelisi. Ts'ebetso ea eona ea othomathiki ka botlalo e etsa hore e be e loketseng bakeng sa ba qalang ba sa tsoa qala indastering. Litaolo tse hlakileng le litaelo tse bonolo ho li latela li netefatsa hore esita le ba nang le boiphihlelo bo fokolang ba ka sebelisa mochini ka kholiseho mme ba fumana liphetho tse holimo.

E 'ngoe ea likarolo tse hlahelletseng tsa mechini ea ho hlapela bareng ea khauta ke bokhoni ba bona ba ho hlahisa liballo tse phethahetseng tsa khauta le silevera tsa boleng bo holimo. Hore na o batla ho theha matsete a khauta le silevera kapa likarolo tse ntle tsa mabenyane, mochini ona o fana ka liphetho tse phethahetseng nako le nako. Boenjiniere bo nepahetseng le thekenoloji e tsoetseng pele ea ho lahla li-vacuum li netefatsa hore mekoallo e hlahisoang ha e na litšila le liphoso 'me e finyella litekanyetso tse thata ka ho fetisisa tsa boleng.

Ntle le tlhahiso ea eona e ikhethang ea boleng, mechini ea ho lahla vacuum ea khauta e boetse e tsejoa ka bokhoni ba eona ba ho qhibiliha ka potlako. Indasteri ea tšepe ea bohlokoa, nako ke ea bohlokoa 'me mochine ona o etselitsoe ho fokotsa ts'ebetso ea tlhahiso. Ka linako tse potlakileng tsa ho qhibiliha, o ka eketsa katleho ea tlhahiso haholo le ho fihlela litlhoko tsa 'maraka o potlakileng ntle le ho senya boleng ba sehlahisoa sa ho qetela.

Ntle le moo, metjhini ea ho lahla vacuum ea khauta e hahiloe hore e tšoarelle le ho shebana le ho tšoarella le ho ts'epahala. Kaho ea eona e tiileng le thepa ea boleng bo holimo e netefatsa hore e khona ho mamella mathata a ts'ebeliso e tsoelang pele, e etsa hore e be letsete le bohlale bakeng sa khoebo ea hau. Ka tlhokomelo e nepahetseng, mochine ona o tla tsoela pele ho fana ka ts'ebetso e babatsehang bakeng sa lilemo tse tlang, ho u fa tharollo e ka tšeptjoang, e sebetsang hantle ea tlhahiso.

Hore na o setsebi se senyane sa mesebetsi ea matsoho kapa moetsi e moholo, mechini ea ho lahla vacuum ea khauta e fana ka tekanyo e phethahetseng ea ho nepahala, lebelo le boiketlo ba tšebeliso. Ho feto-fetoha ha eona ho etsa hore e tšoanelehe bakeng sa lits'ebetso tse fapaneng, ho tloha ho ho theha litšepe tsa khauta tse entsoeng ka tloaelo ho isa ho tse ngata tse hlahisang mehala ea khauta e tloaelehileng. Ho sa tsotellehe hore na litlhoko tsa hau tsa tlhahiso ke life, mochine ona o ka finyella le ho feta litebello tsa hau.

Ka kakaretso, mechini ea ho lahla li-vacuum tsa khauta ke tharollo ea mantlha bakeng sa ba batlang ho hlahisa liballo tsa boleng bo holimo tsa khauta le silevera habonolo le ka mokhoa o atlehileng. Ts'ebetso ea eona e ikemetseng ka botlalo, bokhoni ba ho qhibiliha ka potlako le tlhahiso ea boleng bo botle e etsa hore e be letlotlo la bohlokoa khoebong efe kapa efe indastering ea tšepe ea bohlokoa. Tsetela mochining ona o tsoetseng pele ho isa bokhoni ba hau ba tlhahiso boemong bo bocha. Eba le phapang eo mochini oa khauta oa vacuum o ka tlisang khoebo ea hau.

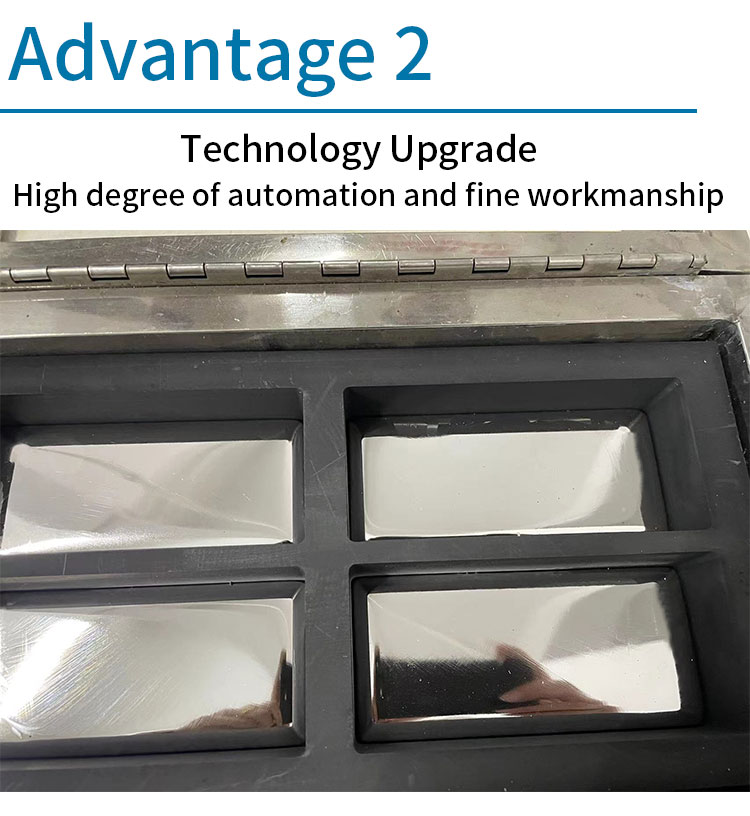

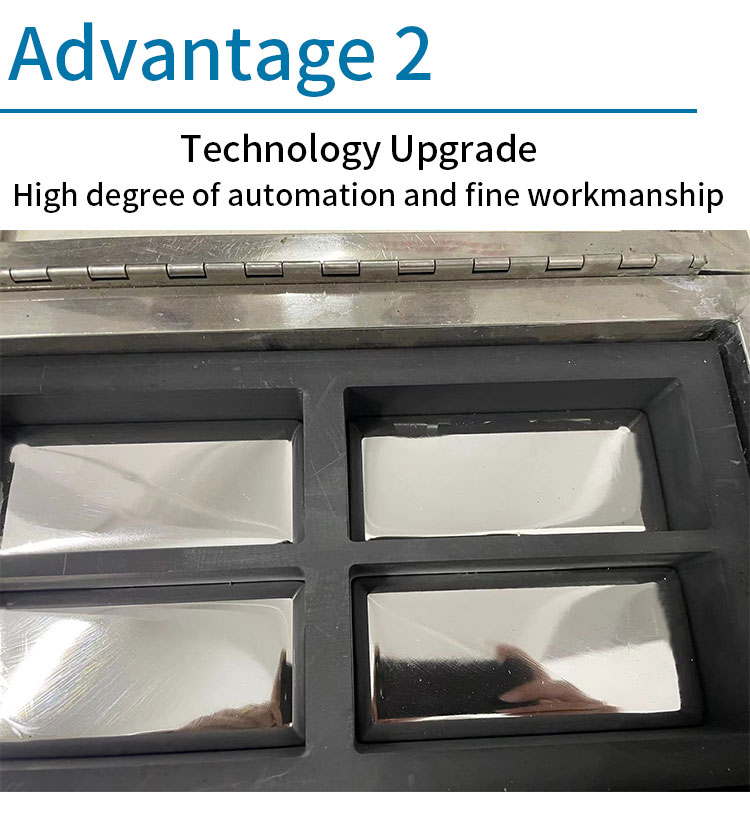

Pontšo ea Sehlahisoa

Sehlooho: Ts'ebetso e rarahaneng ea ho hloekisa khauta le ho etsa li-ingot ka har'a indasteri

Lefatšeng la litšepe tsa bohlokoa, khauta e na le sebaka se khethehileng. Khoheli le boleng ba eona li entse hore e be ntho e batloang ho theosa le lilemo tse makholo, 'me indasteri ea ho hloekisa khauta e na le karolo ea bohlokoa ho netefatsa hore khauta eo re e sebelisang mabenyaneng, lisebelisoa tsa elektroniki le matsete a kopana le maemo a holimo a bohloeki le phello ea boleng. Karolo ea bohlokoa ea indasteri ke ts'ebetso ea ho akhela ingot ea khauta, e fetolang khauta e hloekisitsoeng hore e be lipampiri tsa khauta tse tšoantšetsang maruo le katleho. Ho blog ena, re tla phenya-phenya mokhoa o rarahaneng oa ho hloekisa le ho lahlela khauta, ho senola mehato e qaqileng e amehang le bohlokoa ba mekhoa ena indastering ea khauta.

Khauta e hloekisang: ho tloha ho ore ho ea ho khauta e hloekileng

Leeto la khauta ho tloha sebopehong sa eona se tala e le borale ho ea tšepeng e benyang eo re e lakatsang le qala ka tšebetso ea tlhoekiso ea khauta. Mokhoa ona o rarahaneng o kenyelletsa mehato e 'maloa, e' ngoe le e 'ngoe e reretsoe ho tlosa litšila le ho finyella boemo bo lakatsehang ba bohloeki. Bohato ba pele ba ho hloekisoa ha khauta ke ho ntša litšila tsa khauta lefatšeng, ebe joale lia silakanya le ho li sila hore e be phofo e ntle. Joale phofo ena e feta letotong la mekhoa ea lik'hemik'hale le ea 'mele e arolang khauta ho liminerale le litšila tse ling.

E 'ngoe ea mekhoa e tloaelehileng ea ho hloekisa khauta ke ho sebelisa cyanide leaching, moo motsoako oa cyanide o sebelisoang holim'a tšepe ea khauta ho qhaqha khauta. Tharollo e hlahisoang ebe e sebetsoa ho khutlisa khauta, e hloekisoang ka ho eketsehileng ka mekhoa e kang ho qhibiliha le electrolysis. Mekhoa ena e kenyelletsa ho sebelisa mocheso o phahameng le liphetoho tsa lik'hemik'hale ho tlosa litšila leha e le life tse setseng, e leng se hlahisang khauta e hloekileng e finyellang litekanyetso tsa bohloeki ba indasteri.

Bohlokoa ba ho Hloeka ho Hloekisa Khauta

Bohloeki ke ntlha ea bohlokoa ts'ebetsong ea ho hloekisa khauta kaha e ama ka ho toba boleng le boleng ba sehlahisoa sa ho qetela. Bohloeki ba khauta bo lekantsoe ka likarate, ha khauta ea 24-karat e le sebopeho se hloekileng ka ho fetisisa 'me se na le khauta ea 99.9%. Ha boleng ba karat bo le tlase, boleng ba khauta bo tlase. Ka mohlala, 18 karat khauta e na le 75% ea khauta le 25% litšepe tse ling. Ho fumana bohloeki bo phahameng ho bohlokoa ho fihlela litlhoko tse thata tsa liindasteri tse itšetlehileng ka khauta, joalo ka tlhahiso ea mabenyane le tlhahiso ea lisebelisoa tsa elektronike.

Ntle le ho finyella litekanyetso tsa bohloeki, ho hloekisa khauta ho boetse ho phetha karolo ea bohlokoa ho netefatsa mekhoa ea boitšoaro le e tsitsitseng ka har'a indasteri. Mekhoa e nang le boikarabelo ea ho hloekisa khauta e kenyelletsa tšebeliso ea mekhoa e baballang tikoloho le ho kenya ts'ebetsong mekhoa e hlokang leeme ea basebetsi e sebetsanang le litaba tse amanang le liphello tsa tikoloho le tsa sechaba tsa mesebetsi ea merafo ea khauta le ea ho hloekisa.

Gold Ingot Casting: Fetolela khauta e hloekisitsoeng hore e be mekoallo ea khauta

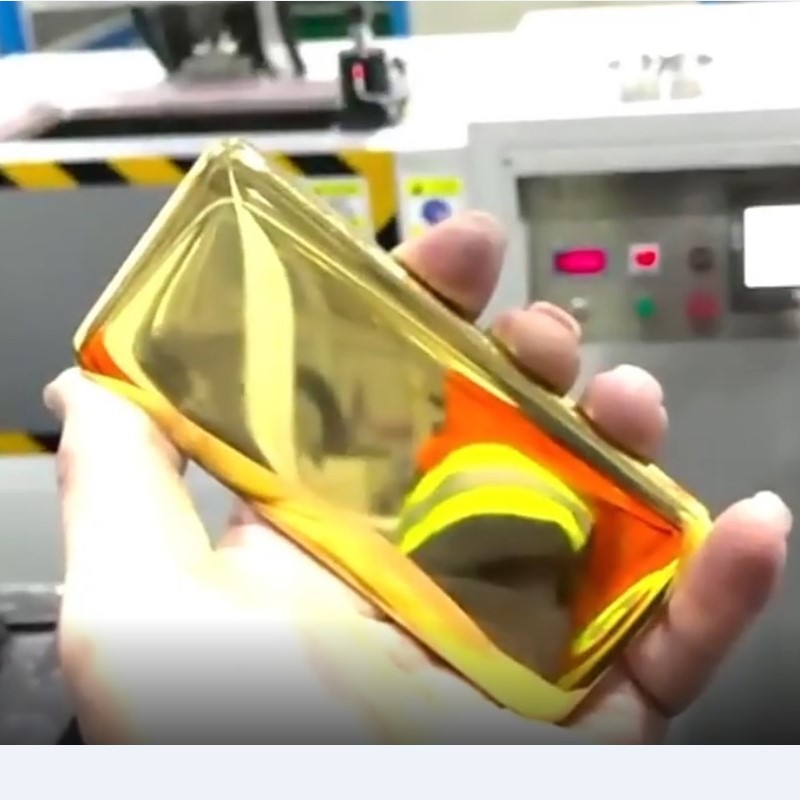

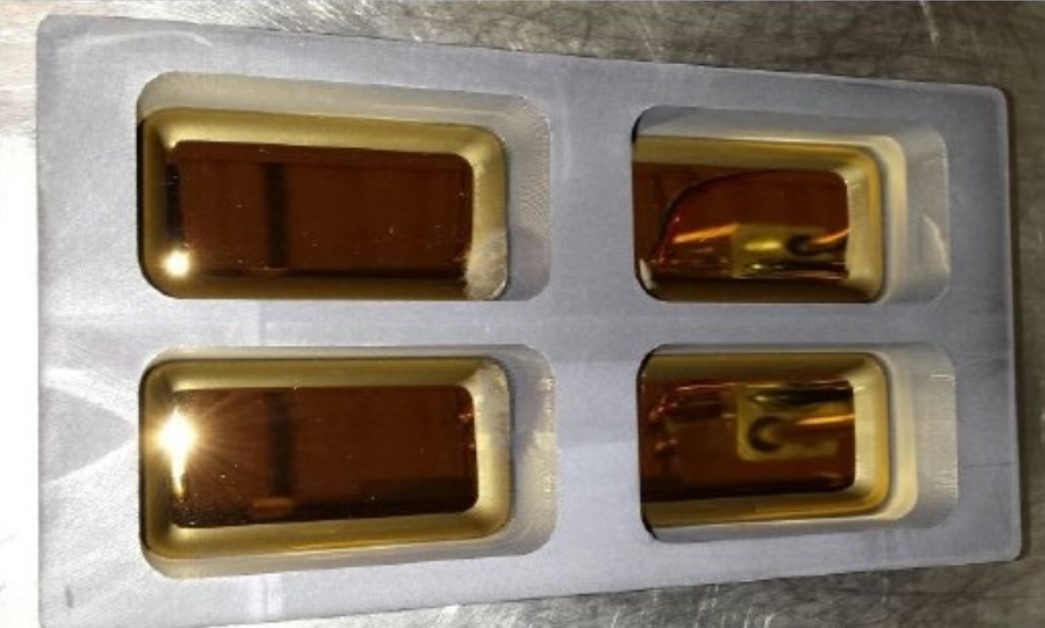

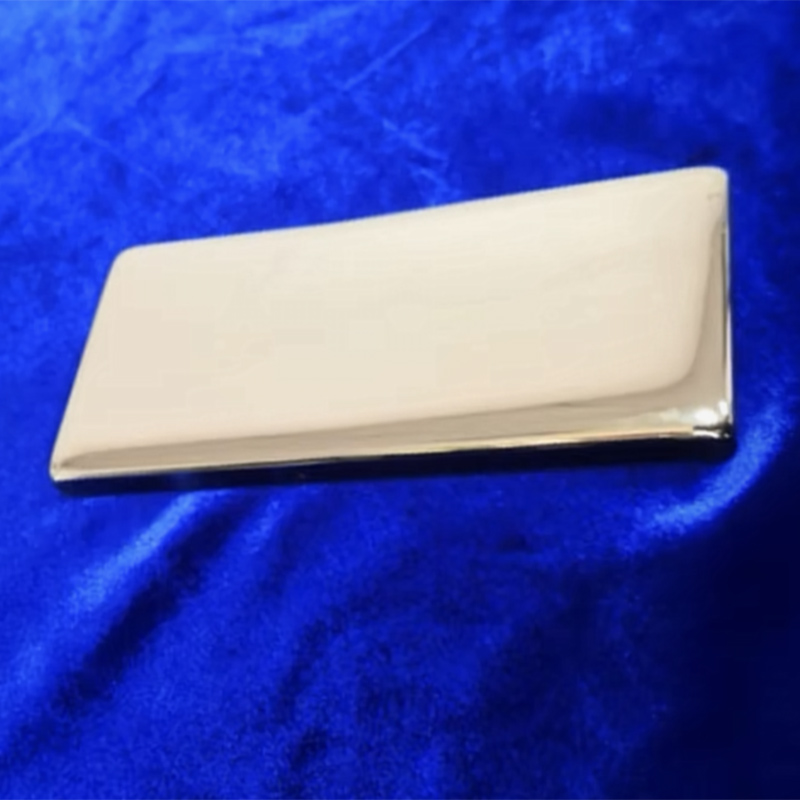

Hang ha khauta e se e hloekisitsoe ho isa bohloeki bo lakatsehang, e ka fetoloa litšepe tsa khauta tse tsejoang e le li-ingots tsa khauta. Ts'ebetso ea ho lahla khauta e kenyelletsa ho tšela khauta e qhibilihisitsoeng ka har'a liforomo ho etsa mekoallo ea khauta e tiileng, mokhoa o bonolo le o tloaelehileng oa khoebo le polokelo. Ts'ebetso ena e hloka ho nepahala le tsebo ea ho etsa bonnete ba hore ingot e hlahisoang e kopana le litlhaloso tse hlokahalang ho latela boima, boholo le bohloeki.

Bohato ba pele ba ho etsa khauta ea ingot ke ho lokisa hlobo, eo hangata e entsoeng ka thepa e tšoarellang e kang graphite kapa tšepe. Hlobo e entsoe ka mokhoa oa ho hlahisa likotoana tsa khauta tsa boima le boholo bo itseng, tse nang le matšoao a bontšang ho hloeka le tšimoloho ea khauta. Hang ha hlobo e se e lokisitsoe, khauta e hloekisitsoeng e qhibilihisoa ka mocheso o phahameng ka har'a crucible, hangata e sebelisa sebōpi sa induction kapa lisebelisoa tse ling tse khethehileng.

Joale khauta e qhibilihisitsoeng e tšeloa ka hloko ka har'a hlobo, e leng mokhoa o hlokang tsebo le ho ela hloko lintlha tse qaqileng ho qoba liphoso leha e le life kapa bofokoli leha e le bofe bo entsoeng ka khauta ea ho qetela. Ka mor'a hore khauta e tiee, hlobo e buloa ho senola ingot ea khauta e sa tsoa etsoa, e ntan'o hlahlojoa le ho tšoauoa ka letšoao la boitsebiso ho paka ho hloeka le bonnete ba eona. Matshwao ana hangata a kenyeletsa boima, bohlweki le letshwao la khamphani e hlwekisang, ho fana ka lesedi la bohlokwa ho bareki le barekisi ba mmarakeng wa kgauta.

Bohlokoa ba ho lahla khauta ka har'a indasteri

Khauta ea ingot casting ke sehokelo sa bohlokoa lipakeng tsa tšebetso ea tlhoekiso ea khauta le 'maraka oa khauta, e fanang ka mokhoa o tloaelehileng le o ka lemohuoang oa khoebo le polokelo ea khauta. Litšepe tsena tsa khauta li sebelisoa haholo molemong oa matsete hammoho le tlhahisong ea mabenyane le lihlahisoa tse ling tsa khauta. Ts'ebetso e hlokolosi ea ho etsa li-ingot e netefatsa hore khauta e kopana le bohloeki bo hlokahalang le litekanyetso tsa boleng, e kenyang tšepo ho bareki le batseteli ba itšetlehileng ka botšepehi ba khauta eo ba e rekang.

Ho feta moo, khauta ea khauta e bapala karolo ea bohlokoa 'marakeng oa lefats'e oa khauta e le mofuta oa lichelete le polokelo ea boleng bo akaretsang. Boima bo lekantsoeng ba khauta le bohloeki bo etsa hore e be e loketseng khoebong ea machaba le matsete, ho nolofatsa litšebelisano le ho fetoha letlotlo le tšepahalang linakong tsa ho hloka botsitso moruong. Ka hona, ts'ebetso ea ho etsa li-ingot e thusa ho eketsa boleng le botsitso ba 'maraka oa khauta, e lumellang phapanyetsano e se nang moeli ea khauta lefatšeng ka bophara.

Bokamoso ba ho hloekisoa ha khauta le ho etsa li-ingot

Ha tlhoko ea khauta e ntse e hola, e susumetsoa ke lintlha tse kang botsitso ba moruo, boqapi ba thekenoloji le bohlokoa ba setso, indasteri ea tlhoekiso ea khauta e tla bapala karolo ea bohlokoa ho fihlela tlhoko ena. Tsoelo-pele ea theknoloji ea ho hloekisa le mekhoa ea moshoelella e lebelletsoe ho tsoela pele ho ntlafatsa katleho le phello ea tikoloho ea mesebetsi ea ho hloekisa khauta, ho netefatsa hore indasteri e finyella litekanyetso tse phahameng ka ho fetisisa tsa boitšoaro le boikarabelo.

Ka mokhoa o ts'oanang, ts'ebetso ea ho lahla ingot ea khauta e kanna ea tsoela pele ho ntlafatsa le ho ntlafatsa, ho tsepamisitsoe ho nepahala, ho iketsetsa le ho itlhophisa ho fihlela litlhoko tse fetohang tsa mmaraka. Tšebeliso ea mekhoa e tsoetseng pele ea ho lahla le thepa e ka ntlafatsa boleng le ho tsitsisa ha li-ingots tsa khauta, ha theknoloji ea digital le tharollo ea blockchain e ka fetola bopaki le ho latella ha li-ingots tsa khauta, ho fana ka pepenene ho bareki le batseteli. le tshireletso.

Qetellong, ho hloekisoa ha khauta le mokhoa oa ho etsa li-ingot ke karolo ea bohlokoa ea indasteri ea khauta 'me e etsa qeto ea boleng, boleng le thekiso ea tšepe ena ea bohlokoa. Ho tloha ka ho tlosoa ka hloko ha litšila nakong ea ho hloekisoa ha khauta ho ea ho ho etsoa ka mokhoa o nepahetseng ha li-ingots tsa khauta, mekhoa ena e bonahatsa boqhetseke le botsebi ba indasteri ea khauta. Ha indasteri e ntse e tsoela pele ho fetoha le ho ikamahanya le litlhoko le maemo a fetohang, bonono le mahlale a ho hloekisa le ho lahlela khauta e ntse e le bohlokoa ho netefatsa boipiletso le boleng bo sa feleng ba khauta lefatšeng la sejoale-joale.

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur

.png)