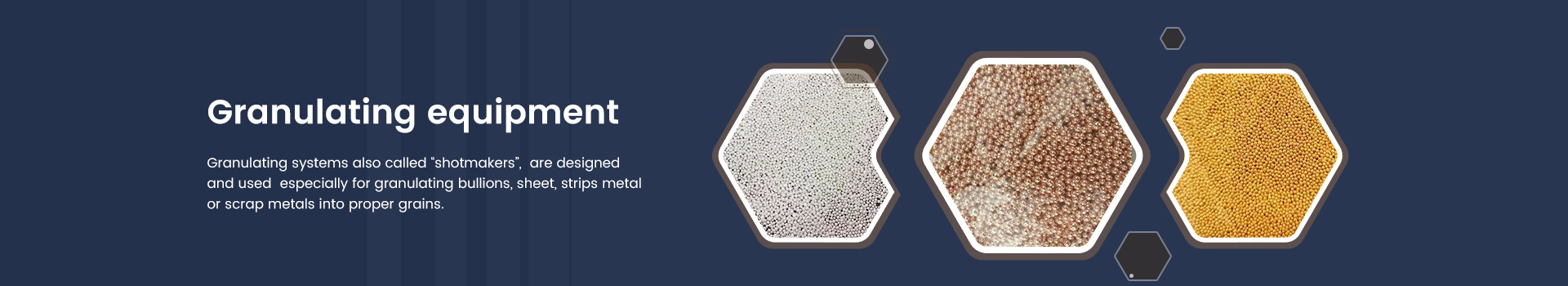

Sistimi ea Granulating

Lisebelisoa tsa granulating tse bitsoang "shotmakers", li etselitsoe le ho sebelisoa haholo-holo bakeng sa li-bullions tse granulating, lakane, li-strips kapa litšepe tse senyehileng hore li be lijo-thollo tse nepahetseng.Litanka tsa granulating li bonolo haholo ho li tlosa bakeng sa ho hloekisoa.Sethapo sa ho hula bakeng sa ho tlosa tanka habonolo.Thepa ea boikhethelo ea mochini o lahlang khatello ea vacuum kapa mochini o tsoelang pele oa ho lahla o nang le tanka ea granulating ke tharollo bakeng sa granulating ka linako tse ling hape.Litanka tsa granulating li teng bakeng sa mechini eohle e hlahang lethathamong la VPC.Mefuta e tloaelehileng ea granulating system e na le tanka e nang le mabili a mane a tsamaeang habonolo le ho tsoa.

-

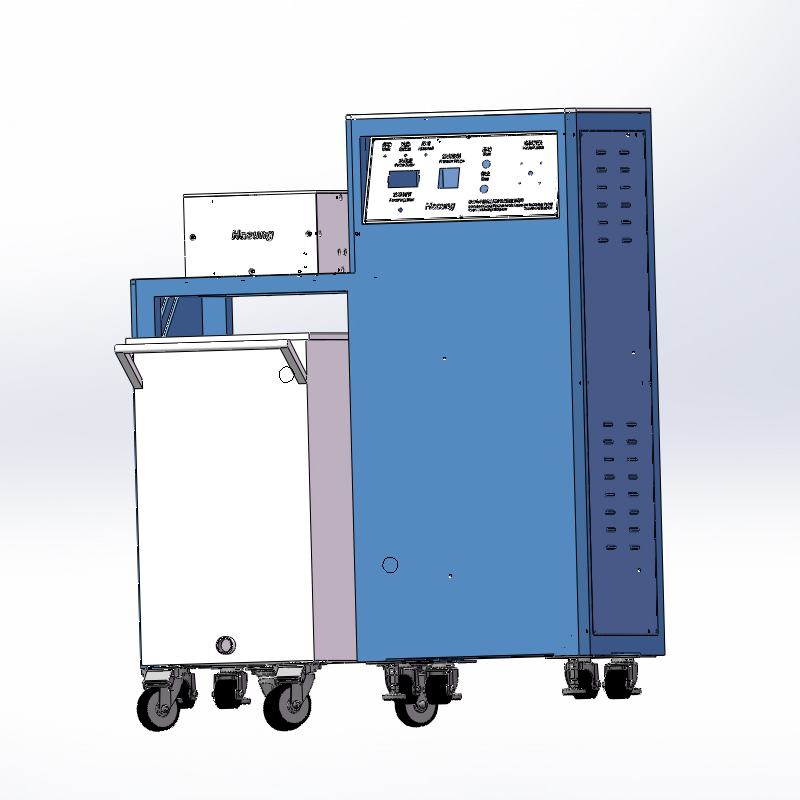

Metal Granulator Machine bakeng sa Khauta Silver Copper 2kg 3kg 5kg 6kg 8kg10kg 15kg

1. Ka taolo ea mocheso, ho nepahala ho fihla ho ±1°C.

2. Moralo oa batho ba bangata, ts'ebetso e bonolo ho feta tse ling.

3. Sebelisa selaoli sa Mitsubishi se tsoang kantle ho naha.

4. Silver Granulator e nang le taolo ea mocheso (Khauta ea Silver Granu Casting Machine, Silver Granulating Machine).

5. Mochine ona o sebelisa theknoloji ea ho futhumatsa e tsoetseng pele ea IGBT, phello ea ho lahla e ntle haholo, tsamaiso e tsitsitse ebile e sireletsehile, bokhoni ba khauta bo qhibilihisitsoeng ke boikhethelo, 'me litlhaloso tsa tšepe tse nang le granulated ke tsa boikhethelo.

6. Lebelo la granulation le potlakile ebile ha le na lerata.Mesebetsi e phethahetseng ea tlhahlobo le ts'ireletso e tsoetseng pele e etsa hore mochini oohle o bolokehe ebile o tšoarelle.

7. Mochine o na le moralo o arohaneng 'me' mele o na le sebaka se eketsehileng sa mahala.

-

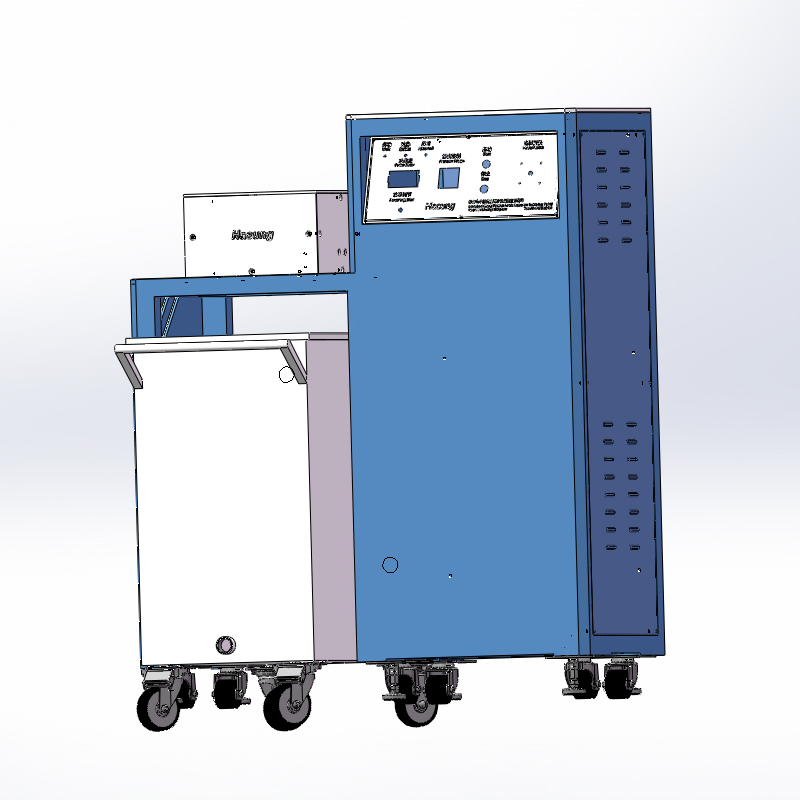

Platinum Granulating System Granulating Machine 10kg

Hasung Platinum Shot Maker Granulating Machine ha e bapisoa le lihlahisoa tse tšoanang 'marakeng, e na le melemo e ikhethang e ke keng ea lekanngoa mabapi le ts'ebetso, boleng, ponahalo, joalo-joalo,' me e thabela botumo bo botle 'marakeng.Hasung e akaretsa mefokolo ea lihlahisoa tse fetileng,' me e tsoela pele. ea li ntlafatsa.Litlhaloso tsa Hasung Platinum Shot Maker Granulating Machine li ka etsoa ho latela litlhoko tsa hau.

Melemo e ka sehloohong ea meloko e mecha ea shotmaker

Ho kenngoa habonolo ha tanka ea granulating e nang le sethala

Tshebetso ea boleng bo phahameng ba granulating

Moralo oa ergonomically le o leka-lekaneng ka ho phethahetseng bakeng sa ho sebetsana ka mokhoa o bolokehileng le o bonolo

Mokhoa o ntlafalitsoeng oa ho phalla ha metsi a pholileng

Karohano e tšepahalang ea metsi le granules -

Vacuum Shot Maker bakeng sa Koporo ea Khauta ea Silver 1kg 2kg 4kg 8kg

Moralo oa sistimi ena ea vacuum granulator e ipapisitse le litlhoko tsa 'nete tsa ts'ebetso ea tšepe ea bohlokoa ka ho sebelisa theknoloji ea sejoale-joale ea theknoloji e phahameng ea ho futhumatsa.

Vacuum granulator e sebelisetsoa ho etsa lithollo tsa boleng bo holimo le tsa boleng bo holimo bakeng sa lirafshoa tsa bohlokoa tse kang khauta, silevera, koporo le lialloys, ho qala ka thepa e tala e qhibilihisitsoeng ke mocheso oa Hasung o kenang moeeng o sirelletsang khase, ebe o oela ka tanka ea metsi e fetang. ka crucible e nang le mekoti e mengata e sebetsang joalo ka seqhetso.

Vacuum granulator e amohela vacuum ka botlalo le ho qhibiliha ha khase e inert le granulating, mochini o ka sisinyeha ka bohona ka ho qhibiliha, ho tsosoa ha motlakase, le sehatsetsing ka phaposing e ts'oarellang ea ts'ireletso ea khase e koetsoeng +, e le hore sehlahisoa se be le litšobotsi tsa ho se be le oxidation, super. tahlehelo e tlase, ha ho li-pores, ha ho khethollo ka 'mala, le ponahalo e ntle e nang le boholo bo lekanang.

Thepa ena e sebelisa sistimi ea taolo ea lenaneo la Mitsubishi PLC, SMC pneumatic le Panasonic servo motor drive le likarolo tse ling tse tsebahalang tsa brand lapeng le kantle ho naha.

-

High Vacuum Granulating System bakeng sa Khauta Silver Copper 20kg 50kg 100kg

High vacuum granulate granulate tsa bohlokoa tšepe likaroloana bakeng sa ho lahlela bonding terata: khauta, silevera le koporo, bonding terata e haholo-holo sebelisoa bakeng sa thepa semiconductor, photovoltaic tjheseletsa thepa, thepa ea bongaka, mahlale a maiketsetso mechine. , lesela la tšepe, kapa likhechana ho etsa lijo-thollo tse nepahetseng.Litanka tsa granulating li bonolo haholo ho li tlosa bakeng sa ho hloekisa.Mechini ea HS-VGR High Vacuum Granulating e fumaneha ka matla a crucible ho tloha ho 20kg ho isa ho 100kg.Lisebelisoa tsa 'mele li sebelisa tšepe e sa hloekang ea 304 e netefatsang boleng ba bophelo bohle bo sebelisoa, hape e nang le moralo oa modular ho phethahatsa boleng bo hlokahalang.

Lisebelisoa tse kholo:

1. Ho lokisoa ha li-alloys ho tsoa ho khauta le master alloy

2. Tokisetso ea likarolo tsa alloy

3. Tokisetso ea li-alloys tse tsoang likarolong

4. Ho hloekisa tšepe e seng e entsoe

5. Ho etsa lithollo tsa tšepe bakeng sa litšebelisano tsa tšepe tsa bohlokoaLetoto la VGR le ile la hlahisoa bakeng sa tlhahiso ea li-granules tsa tšepe tse nang le boholo ba lijo-thollo pakeng tsa 1.5 mm le 4mm.Sistimi e ipapisitse le li-unit tsa Hasung granulation, empa likarolo tsohle tsa bohlokoa, haholo sistimi ea jete, ke lintlafatso tse ikhethang.

Bokhoni bo boholo joalo ka sistimi ea vacuum granulating ea 100kg ke boikhethelo ho ba le sistimi e laolang ea Mitsubishi PLC Touch Panel.

Thepa ea boikhethelo ea khatello ea vacuum kapa mochini o tsoelang pele oa ho lahla o nang le tanka ea granulating ke tharollo e loketseng bakeng sa granulating ka linako tse ling.Litanka tsa granulating li fumaneha bakeng sa mechini eohle ea letoto la VC.

Melemo ea mantlha ea meloko e mecha ea sethunya:

1. Ho kenngoa habonolo ha tanka ea granulating

2. Ho fetoha ka potlako pakeng tsa mokhoa oa ho lahla le granulating

3. Moralo oa ergonomically le o leka-lekaneng ka ho phethahetseng bakeng sa ho sebetsana ka mokhoa o sireletsehileng le o bonolo

4. Boitšoaro bo nepahetseng ba ho phalla ha metsi a pholileng

5. Karohano e tšepahalang ea metsi le granules

6. E matla ka ho fetisisa le e sebetsang hantle bakeng sa lihlopha tsa ho hloekisa litšepe tsa bohlokoa.

7. Ho boloka matla, ho qhibiliha ka potlako. -

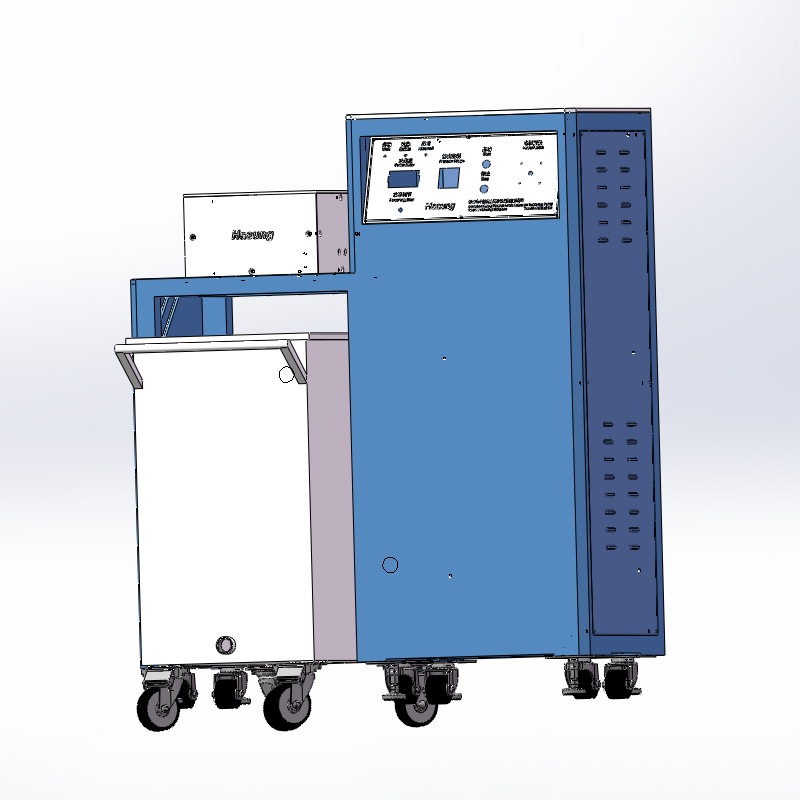

Metal Granulating Machine bakeng sa Khauta Silver Copper Alloy 20kg 30kg 50kg 100kg 150kg

1. Ka taolo ea mocheso, ho nepahala ho fihla ho ±1°C.

2. Moralo oa batho ba bangata, ts'ebetso e bonolo ho feta tse ling.

3. Sebelisa selaoli sa Mitsubishi se tsoang kantle ho naha.

4. Silver Granulator e nang le taolo ea mocheso (Khauta ea Silver Granu Casting Machine, Silver Granulating Machine).

5. Mochine ona o sebelisa theknoloji ea ho futhumatsa e tsoetseng pele ea IGBT, phello ea ho lahla e ntle haholo, tsamaiso e tsitsitse ebile e sireletsehile, bokhoni ba khauta bo qhibilihisitsoeng ke boikhethelo, 'me litlhaloso tsa tšepe tse nang le granulated ke tsa boikhethelo.

6. Lebelo la granulation le potlakile ebile ha le na lerata.Mesebetsi e phethahetseng ea tlhahlobo le ts'ireletso e tsoetseng pele e etsa hore mochini oohle o bolokehe ebile o tšoarelle.

7. Mochine o na le moralo o arohaneng 'me' mele o na le sebaka se eketsehileng sa mahala.

-

Thepa e kopaneng ea tšepe ea tšepe ea granulator bakeng sa silevera ea khauta

Baetsi ba lithunya ba tšepe ba boholo bo bonyenyane.Ka taolo ea mocheso, ho nepahala ho fihla ho ±1°C.

Moralo oa batho ba bangata, ts'ebetso e bonolo ho feta tse ling.

Sebelisa selaoli sa Mitsubishi se tsoang kantle ho naha.

Etsa kopo bakeng sa mochini oa VC oa li-vacuum pressure cast, o nang le tanka ea metsi ea 304 SS.Granulator e nang le taolo ea mocheso (Mochini oa ho Lahlela Lithollo tsa Khauta tsa Silver Granulating, Mochini oa Silver Granulating).

Mochini ona o amohela theknoloji ea ho futhumatsa e tsoetseng pele ea Jeremane IGBT, phello ea ho lahla e ntle haholo, sistimi e tsitsitse ebile e bolokehile, bokhoni ba khauta e qhibilihisitsoeng ke boikhethelo, 'me litlhaloso tsa tšepe tse granulated ke tsa boikhethelo.Lebelo la granulation le potlakile ebile ha le na lerata.Mesebetsi e phethahetseng ea tlhahlobo le ts'ireletso e tsoetseng pele e etsa hore mochini oohle o bolokehe ebile o tšoarelle.Mochine o na le moralo o arohaneng 'me' mele o na le sebaka se eketsehileng sa mahala.E sebelisa ntle le konpresser ea moea, ho lahla ka sethibelo sa ho bula ka matsoho.

Sistimi ena ea granulating ea AG Series e loketse matla a manyane ho tloha ho 1kg ho isa ho 6kg (khauta), e loketse bareki ba nang le sebaka se senyane.

Granulation ea tšepe ke eng?

Granulation (ho tsoa ho Selatine: granum = "thollo") ke mokhoa oa setei sa khauta moo bokaholimo ba lehakoe le khabisoang ka likotoana tse nyane tsa tšepe ea bohlokoa, tse bitsoang li-granules, ho latela sebopeho sa moralo.Lintho tsa khale ka ho fetisisa tsa ho epolloa ha lintho tsa khale tsa mabenyane a entsoeng ka mokhoa ona li ile tsa fumanoa mabitleng a borena a Ure, Mesopotamia 'me li khutlela ho 2500 BC Ho tloha sebakeng sena, mokhoa ona o ile oa ata ho Anatolia, Syria, ho Troy (2100 BC) 'me qetellong ho Etruria. (lekholong la bo8 la lilemo BC).E bile ho nyamela butle-butle ha setso sa Etruscan pakeng tsa lekholo la boraro le la bobeli la lilemo BC ho ileng ha ikarabella bakeng sa ho fokotseha ha granulation. phepelo ea bona e makatsang ea granulation2 ea phofo e ntle ntle le tšebeliso e hlakileng ea solder e thata.

Mohlomong granulation ke eona e makatsang ka ho fetesisa le e khahlang ka ho fetesisa ea mekhoa ea khale ea mekhabiso.E tsebisitsoe ke litsebi tsa mesebetsi ea matsoho Fenici le Greci ho ea Etruria lekholong la bo8 la lilemo BC, moo tsebo ea metallurgy le tšebeliso ea litšepe tsa bohlokoa li neng li se li ntse li le boemong bo tsoetseng pele, litsebi tsa litsebi tsa Etruscan tsa khauta li ile tsa iketsetsa mokhoa ona oa ho etsa mesebetsi ea bonono ea ho rarahana le botle bo ke keng ba lekanngoa.

Nakong ea halofo ea pele ea lilemo tsa bo-1800 ho ile ha etsoa liepollo tse 'maloa sebakeng sa Roma (Cerveteri, Toscanella le Vulci) le Southern Russia (lihlekehleke tsa Kertch le Taman) tse ileng tsa senola mabenyane a khale a Etruscan le a Segerike.Mabenyane ana a ne a khabisitsoe ka granulation.Mabenyane a ile a hlokomeloa ke Lelapa la Castellani la mabenyane a neng a ameha haholo lipatlisisong tsa khale tsa mabenyane.Lintho tse fumanoeng libakeng tsa lepato tsa Etruscan li ile tsa khahla batho haholo ka lebaka la tšebeliso ea tsona ea li-granules tse ntle haholo.Alessandro Castellani o ile a ithuta lintho tsena tsa khale ka ho qaqileng e le ho leka ho manolla mokhoa oa tsona oa ho etsa lintho.E bile mathoasong a lekholo la bo20 la lilemo, ka mor'a lefu la Castellani, moo papali ea colloidal/eutectic soldering e ileng ea qetella e rarollotsoe.

Le hoja sephiri se ile sa lula e le sephiri ho Castellanis le batho ba mehleng ea bona, mabenyane a Etruscan a neng a sa tsoa sibolloa a ile a etsa hore ho be le tsosoloso ea mabenyane a lintho tsa khale hoo e ka bang ka bo-1850.Ho ile ha sibolloa mekhoa ea ho etsa khauta e ileng ea thusa Castellani le ba bang hore ba boele ba boele ka botšepehi mabenyane a mang a khale ka ho fetisisa a kileng a epolloa.Bongata ba mekhoa ena e ne e fapane haholo le e neng e sebelisoa ke Ma-Etruscans leha ho le joalo e ntse e fana ka sephetho se ka khonehang.Lintho tse 'maloa tsa mabenyane ana a Tsosoloso ea Boepolli ba Lintho tsa khale li se li le pokellong ea bohlokoa ea mabenyane lefatšeng ka bophara, hammoho le balekane ba bona ba khale.

LIKOANE

Li-granules li entsoe ka alloy e tšoanang le tšepe eo li tla sebelisoa ho eona.Mokhoa o mong o qala ka ho phutha lesela le tšesaane haholo la tšepe le ho seha litjellane tse tšesaane haholo moeling.Motsoako o fokotsoe 'me phello e ba li-square tse ngata tse nyenyane kapa li-platelet tsa tšepe.Mokhoa o mong oa ho etsa lijo-thollo o sebelisa terata e tšesaane e pota-potiloeng ho pota-pota mandrel e tšesaane, joalo ka nale.Joale coil e khaoloa ka mehele e menyenyane haholo.Sena se etsa mehele e lekanang haholo e hlahisang li-granules tse boholo bo lekanang.Sepheo ke ho theha likarolo tse ngata tse lekanang ka boholo tse nang le bophara bo sa feteng 1 mm.

Li-platelet tsa tšepe kapa li-jump rings li koahetsoe ka phofo ea mashala ho thibela ho khomarela hammoho nakong ea ho thunya.Botlaaseng ba crucible bo koahetsoe ke lesela la mashala 'me likotoana tsa tšepe li fafatsoa ka hore li arohane ka tsela e lekanang ka hohle kamoo ho ka khonehang.Sena se lateloa ke lesela le lecha la phofo ea mashala le likotoana tse ling tsa tšepe ho fihlela crucible e ka ba likarolo tse tharo tse tletseng.The crucible e chesoa ka sebōpi kapa ka ontong, 'me likotoana tsa tšepe tsa bohlokoa li pota-pota ka likaroloana tse nyenyane mocheso o qhibilihisang bakeng sa motsoako oa tsona.Maqhubu ana a sa tsoa thehoa a tloheloa hore a phole.Hamorao li hloekisoa ka metsing kapa, haeba mokhoa oa ho kopanya o tla sebelisoa, o kenngoe ka asiti.

Li-granules tsa boholo bo sa lekaneng li ke ke tsa hlahisa moralo o khahlisang.Kaha ho ke ke ha khoneha hore setei sa khauta se etse likaroloana tse lekanang hantle tsa bophara bo lekanang hantle, li-granules li tlameha ho hlophisoa pele li sebelisoa.Letoto la li-sieve li sebelisoa ho hlophisa li-granules.

U etsa khauta ea khauta joang?

Na mokhoa oa ho etsa khauta o tšela khauta e qhibilihisitsoeng butle-butle ka metsing ka mor'a hore ue chese?Kapa u e etsa kaofela ka nako e le 'ngoe?Sepheo sa ho etsa khauta ho e-na le li-ingots ect.

Khauta e thunngoa ha e bōptjoe ka ho tšolloa ho tloha molomong oa setshelo.E tlameha ho ntšoa ka nozzle.U ka etsa e bonolo ka ho phunya lesoba le lenyenyane (1/8") ka tlas'a sejana se qhibilihang, se neng se tla beoa holim'a sejana sa hau sa metsi, 'me lebone le bapala holim'a sejana, ho potoloha lesoba. khauta ho tloha ho leqhoa sejaneng ha e tlosoa sejaneng se qhibilihisang seo phofo ea khauta e qhibilihang ho eona.

Shot e ratoa ke ba sebelisang khauta, hobane e etsa hore ho be bonolo ho lekanya tekanyo e batloang.Litei tsa khauta tse bohlale ha li qhibilihe khauta e ngata ka nako e le 'ngoe, ho seng joalo li ka lebisa ho li-castings tse nang le bokooa (li-gas inclusions).

Ka ho qhibiliha feela palo e hlokahalang, chelete e nyenyane e setseng (sprue) e ka qhibiliha ka beche e latelang, ho netefatsa hore khauta e qhibisitsoeng hape ha e bokelle.

Bothata ba ho qhibilihisa khauta nako le nako ke hore tšepe ea motheo (eo hangata e leng koporo, empa e sa lekanyetsoa ho koporo) e hlahisa oxidize 'me e qala ho hlahisa khase e bokellanang ka lipokothong tse nyenyane tsa li-castings.Bongata ba mabenyane a mang le a mang a etsang ho lahla o bile le boiphihlelo boo, 'me hangata o ikarabella hore na ke hobane'ng ha a sa rate, kapa a sa rate ho sebelisa khauta e kileng ea sebelisoa.