Thepa e kopaneng ea tšepe ea tšepe ea granulator bakeng sa silevera ea khauta

Tekheniki Parameters

| Mohlala No. | HS-GS2 | HS-GS3 | HS-GS4 | HS-GS5 | HS-GS6 | HS-GS8 |

| Palo ea li-volts | 220V, 50/60Hz, Mokhahlelo o le mong / 380V, 50/60Hz, 3 Phase | |||||

| Matla | 8KW | 10KW | 15KW | |||

| Max Temp | 1500°C | |||||

| Bokhoni (Khauta) | 2kg | 3kg | 4kg | 5kg | 6kg | 8kg |

| Nako ea ho qhibiliha | 2-3 mets. | 3-5 mets. | ||||

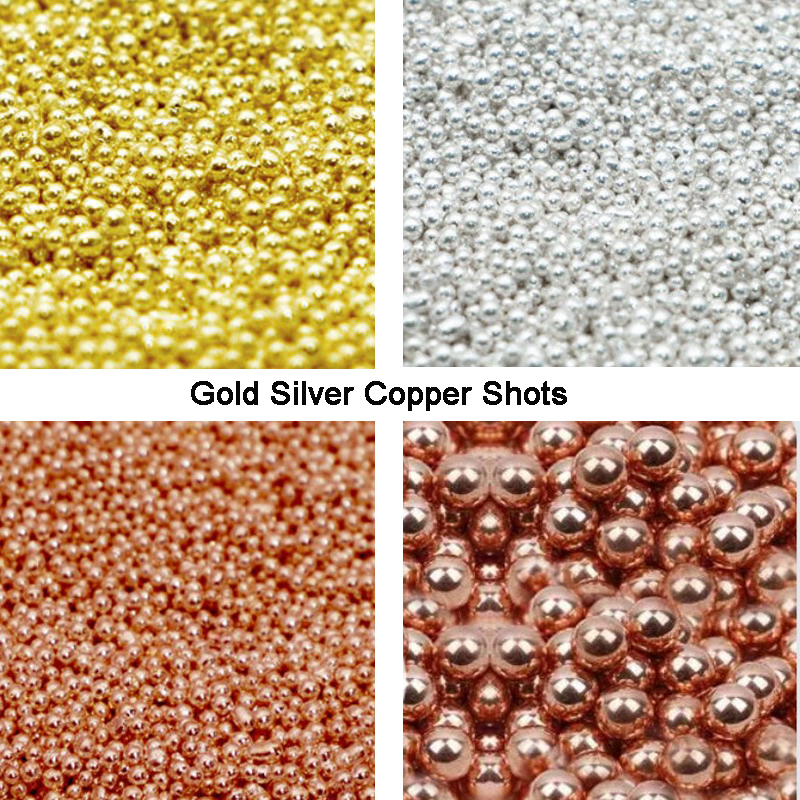

| Kopo | Khauta, K khauta, silevera, koporo le lisebelisoa tse ling | |||||

| Phepelo ea moea | Moea oa compressor | |||||

| Ho Nepaha ha Nako | ±1°C | |||||

| Mohloli oa mocheso | Thermocouple | |||||

| Mofuta o phodileng | Sehatsetsi (se rekisoang ka thoko) kapa Metsi a mathang | |||||

| Litekanyo | 1100*930*1240mm | |||||

| Boima ba 'mele | Hoo e ka bang. 180kg | Hoo e ka bang. 200kg | ||||

Pontšo ea Sehlahisoa

Sehlooho: Karolo ea granulator ea tšepe ts'ebetsong ea ho hloekisa khauta

Ho hloekisoa ha khauta ke ts'ebetso e hlokolosi e kenyelletsang mekhahlelo e mengata le lisebelisoa ho ntša khauta e hloekileng sebakeng sa eona se tala. E 'ngoe ea likarolo tsa bohlokoa tsa lisebelisoa ts'ebetsong ena ea ho hloekisa ke granulator ea tšepe. Bukeng ena, re tla shebana le karolo ea tšepe ea granulator ho hloekiseng khauta le hore na e thusa joang ho ntša khauta e hloekileng.

Granulator ea tšepe ke eng?

Pele re ikakhela ka setotsoana karolong ea tšepe ea ho hloekisa khauta, a re qaleng ka ho utloisisa hore na granulator ea tšepe ke eng le hore na e sebetsa joang. Granulator ea tšepe ke mochini o etselitsoeng ho pshatla makumane a tšepe hore e be likaroloana tse nyane, tse boholo bo lekanang kapa likotoana. E atisa ho sebelisoa indastering ea ho tsosolosa le ea tsamaiso ea litšila ho sebetsana le litšepe tse senyehileng le ho li fetola ka mokhoa o laolehang haholoanyane bakeng sa ts'ebetso e tsoelang pele.

Karolo ea granulator ea tšepe ho hloekisa khauta

Ho hloekisong ha khauta, granulator ea tšepe e bapala karolo ea bohlokoa mothating oa pele oa ts'ebetso ea thepa e tala. Mona ke litlatsetso tsa eona tšebetsong e akaretsang ea tlhoekiso:

1. Phokotso ea likhechana tsa tšepe

Nakong ea ts'ebetso ea ho hloekisa khauta, mefuta e sa tšoaneng ea litšila tsa tšepe e hlahisoa, ho kenyelletsa le likaroloana tse setseng, litšila tsa elektronike le lisebelisoa tse ling tse nang le tšepe. Lisebelisoa tsena li hloka ho fokotsa boholo ho thusa ho tsoela pele ho sebetsa. Mona ke moo li-granulator tsa tšepe li kenang teng. E silakanya hantle le likotoana tsa tšepe tsa pellets, e theha phepelo e laolehang haholoanyane bakeng sa mehato e latelang ea tlhoekiso.

2. Ho arohana ha thepa e seng khauta

Hang ha seretse sa tšepe se kentsoe granulated, mohato o latelang tšebetsong ea tlhoekiso ea khauta ke ho arola thepa eo e seng ea khauta ho likarolo tse nang le khauta. Tšepe ea granular e tsoela pele ka mekhoa e meng ea karohano e kang karohano ea makenete le karohano e thehiloeng ho teteaneng ho arola thepa e nang le khauta ho litšila tse ling tsa tšepe. Boholo bo lekanang le sebōpeho sa tšepe ea granular e thusa mekhoa ena ea karohano, ho etsa hore mokhoa ona o atlehe haholoanyane.

3. Ntlafatsa sebaka se ka holimo bakeng sa ts'ebetso ea lik'hemik'hale

Ka mor'a hore lisebelisoa tse seng tsa khauta li arohane, likaroloana tse nang le khauta tse granular li kenngoa ka lik'hemik'hale ho ntša khauta e hloekileng. Sebopeho sa likaroloana tsa thepa se fana ka sebaka se seholoanyane, se lumellang lik'hemik'hale ho phunyeletsa le ho sebetsana le likaroloana tsa khauta ka katleho. Sena se fella ka ts'ebetso e phahameng ea ho hula le ts'ebetso ea tlhoekiso e phethahetseng.

4. Ntlafatsa mekhoa ea ho qhibilihisa le ho lahla

Hang ha khauta e ntšoa lesela la granular, e tsoela pele ho sebetsoa ka ho qhibiliha le ho lahla ho etsa li-ingots tsa khauta kapa libopeho tse ling tse lakatsehang. Mofuta oa granular oa khauta o nolofatsa mokhoa oa ho qhibiliha hobane o chesa le ho qhibilihisa thepa ka tsela e tšoanang. Sena se hlahisa lihlahisoa tsa khauta tsa boleng bo holimo tse nang le maemo a tsitsitseng a bohloeki.

Ka kakaretso, li-granulator tsa tšepe li bapala karolo ea bohlokoa methating ea pele ea ho hloekisoa ha khauta ka ho lokisa lisebelisoa tse tala bakeng sa ts'ebetso e tsoelang pele, ho khothaletsa karohano e ntle ea thepa eo e seng ea khauta, ho eketsa sebaka sa tšebetso ea lik'hemik'hale, le ho ntlafatsa lits'ebetso tsa ho qhibiliha le ho lahla.

Bohlokoa ba mekhoa e metle ea ho hloekisa khauta

Mokhoa o hloahloa oa ho hloekisa khauta o bohlokoa ho netefatsa bohloeki le boleng ba sehlahisoa sa ho qetela sa khauta. Ebang e sebelisetsoa ho etsa mabenyane, merero ea matsete, kapa mesebetsi ea indasteri, khauta e hloekileng e nkoa e le ea bohlokoa haholo ebile e batloa. Ka hona, karolo ea lisebelisoa tse kang li-pelletizers tsa tšepe ho hloekisa khauta ho isa bohloeki bo hlokahalang le boleng bo ke keng ba fetisoa.

Ntle le likarolo tsa tekheniki, ts'ebetso e sebetsang ea tlhoekiso ea khauta e boetse e kenya letsoho molemong oa ho tšoarella tikolohong. Ka ho laola le ho sebetsana ka katleho le litšila tsa tšepe, ho kenyeletsoa litšila tsa elektronike le likarolo tse lahliloeng, indasteri ea ho hloekisa e ka fokotsa phello ea tikoloho ea merafo ea khauta le ho kenya letsoho tsamaisong e tsitsitseng ea lisebelisoa.

ha re phethela

Ka bokhutšoanyane, li-granulator tsa tšepe li bapala karolo ea bohlokoa ts'ebetsong ea ho hloekisoa ha khauta, ho kenyelletsa le ho lokisa lisebelisoa tse tala, ho thusa karohano e ntle, ho ntlafatsa kalafo ea lik'hemik'hale, le ho ntlafatsa lits'ebetso tsa ho qhibiliha le ho lahla. Tlatsetso ea eona katlehong e akaretsang le boleng ba tlhoekiso ea khauta e ke ke ea hlokomolohuoa. Ha tlhokahalo ea khauta e hloekileng e ntse e hōla, mekhoa e metle ea ho hloekisa, e tšehetsoeng ke lisebelisoa tse tsoetseng pele tse kang li-granulator tsa tšepe, li ntse li le bohlokoa haholo ho finyella litlhoko tsa indasteri bakeng sa lihlahisoa tsa khauta tsa boleng bo phahameng.

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur