Hasung T2 Jewelry Vacuum Pressure Casting Machine

Hobaneng U Khetha mochini oa Hasung Vacuum Pressure Casting?

Hasung T2 Vacuum Casting Machines ha e bapisoa le lik'hamphani tse ling

1. Ts'ebetso e nepahetseng ea ho lahla

2. Lebelo le letle la ho qhibiliha. Lebelo la ho qhibiliha le ka hare ho metsotso e 2-3.

3. Khatello e matla ea ho lahla.

4. Likarolo tsa mantlha tsa Hasung ke lihlahisoa tse tsebahalang tse tsoang malapeng, Japane le Germanu.

5. Ts'ebetso e nepahetseng ea ho lahla

6. Tšehetsa mehopolo ea lenaneo la 100

7. Ho boloka matla. Ka tšebeliso e tlase ea matla 10KW 380V 3 phase.

8. Ho sebelisa naetrojene kapa argon feela, ha ho hlokahale ho hokahanya le moea oa compressor.

Tekheniki Parameters

| Mohlala No. | HS-T2 |

| Palo ea li-volts | 380V, 50/60Hz, mekhahlelo e 3 |

| Phepelo ea motlakase | 10KW |

| Max Temp | 1500°C |

| Nako ea ho qhibiliha | 2-3 mets. |

| Khase e Sireletsang | Argon / naetrojene |

| Ho Nepaha ha Nako | ±1°C |

| Bokhoni (Khauta) | 24K: 2.0Kg, 18K: 1.55Kg, 14K: 1.5Kg, 925Ag: 1.0Kg |

| Molumo oa Crucible | 242CC |

| Boholo ba botlolo | 5"x12" |

| Pumpu ea Vacuum | Pompo ea vacuum ea boleng bo holimo |

| Kopo | Khauta, K khauta, silevera, koporo le lisebelisoa tse ling |

| Mokhoa oa ts'ebetso | Senotlolo se le seng se phethela tšebetso eohle ea ho lahla |

| Mofuta o phodileng | Sehatsetsi (se rekisoang ka thoko) kapa Metsi a mathang |

| Litekanyo | 800*600*1200mm |

| Boima ba 'mele | hoo e ka bang. 230kg |

Pontšo ea Sehlahisoa

Sehlooho: Tsoelo-pele ea Theknoloji ea ho Lahlela Mabenyane a Khauta: Ho Tloha Mehlaleng ea Khale ho ea ho Mecha ea Sejoale-joale

Ka lilemo tse makholo, mabenyane a khauta e bile letšoao la leruo, boemo le botle. Ho tloha mehleng ea khale ho ea ho feshene ea kajeno, khahleho ea khauta e ntse e tšoana. E 'ngoe ea mekhoa ea bohlokoa ea ho theha mabenyane a khauta ke ho lahla, e fetohileng haholo ha nako e ntse e ea. Ka blog ena, re tla hlahloba leeto le tsotehang la theknoloji ea ho etsa mabenyane a khauta, ho tloha tsoelo-peleng ea eona ea pele ho fihlela mekhoa ea kajeno ea mekhoa e metle.

Theknoloji ea Khale: Ho Tsoaloa ha Khauta ea Khauta

Nalane ea ho etsa khauta e ka saloa morao ho tloha mehleng ea khale e kang Egepeta, Mesopotamia le Chaena. Litsebi tsena tsa khale tsa mesebetsi ea matsoho li ile tsa qapa mekhoa ea motheo ea ho etsa lintho ka libotlolo tse bonolo tse entsoeng ka letsopa, lehlabathe kapa lejoe. Mokhoa ona o kenyelletsa ho futhumatsa khauta ho fihlela e fihla boemong ba ho qhibiliha ebe e tšela ka har'a hlobo e lokiselitsoeng ho etsa mabenyane.

Le hoja mekhoa ena ea khale e ne e le ea bohlokoa bakeng sa nako ea bona, e ne e lekanyelitsoe ka ho nepahala le ho rarahana. Mabenyane a hlahisoang hangata a na le ponahalo e thata le e tala, e haelloang ke lintlha tse ntle le mekhabiso e rarahaneng e khethollang mabenyane a kajeno a khauta.

Tsoelo-pele ea Mehleng e Bohareng: Phallo ea Ho Lahla Wax e Lahlehileng

Nakong ea Mehla e Bohareng, tsoelo-pele e kholo ea theknoloji ea ho lahla khauta e etsahetse ka nts'etsopele ea theknoloji e lahlehileng ea ho lahla boka. Mokhoa ona o ile oa fetola mokhoa oa ho etsa lintho, oa lumella litsebi tsa mesebetsi ea matsoho ho etsa likotoana tse rarahaneng le tse qaqileng tsa mabenyane.

Mokhoa o lahlehileng oa ho lahla boka o akarelletsa ho etsa mohlala oa boka ba mabenyane a mabenyane a lakatsehang, ebe o kenngoa ka har'a hlobo e entsoeng ka samente kapa letsopa. Hlobo ea futhumala, e etsa hore boka ba metsi bo qhibilihe ebe bo fetoha mouoane, ho siea sekoti ka sebōpeho sa mohlala oa pele oa boka. Ka mor'a moo, khauta e qhibilihisitsoeng e ne e tšeloa ka mokoting, e leng se etsang hore ho be le setšoantšo se nepahetseng le se qaqileng sa mohlala oa boka.

Theknoloji ena e ile ea tšoaea khatelo-pele e khōlō tsebong ea ho etsa khauta, e lumella litsebi tsa mesebetsi ea matsoho ho hlahisa mabenyane a nang le lipaterone tse rarahaneng, mosebetsi o thata oa li-filigree, le libopeho tse ntle tseo pele li neng li ke ke tsa finyelloa.

Phetoho ea Liindasteri: Mokhoa oa ho Lahlela ka Mechini

Phetoho ea Liindasteri e ile ea tlisa leqhubu la tsoelo-pele ea theknoloji e ileng ea fetola mekhoa ea tlhahiso liindastering tse fapaneng, ho kenyeletsoa tlhahiso ea mabenyane. Nakong ena, ho ile ha hlahisoa mekhoa ea mechine ea ho lahla, e lumellang tlhahiso e ngata ea mabenyane a khauta.

E 'ngoe ea lintlafatso tsa mantlha e ne e le nts'etsopele ea mochini oa centrifugal casting, o sebelisitseng matla a centrifugal ho abela khauta e qhibilihisitsoeng ka har'a hlobo. Ts'ebetso ena ea othomathike e eketsa haholo ts'ebetso le botsitso ba ho lahla khauta, e bakang tlhahiso e phahameng le likotoana tsa mabenyane a tloaelehileng.

Boqapi ba sejoale-joale: moralo oa dijithale le khatiso ea 3D

Lilemong tse mashome tsa morao tjena, ho hlaha ha moralo oa dijithale le theknoloji ea khatiso ea 3D ho fetotse sebopeho sa mabenyane a khauta. Litlhahiso tsena tse tsoetseng pele li fetotse tsela eo meralo ea mabenyane e bōpiloeng ka eona le ho fetoleloa ka lintho tse bonahalang.

Software ea meralo ea dijithale e thusa baqapi ba mabenyane ho etsa mefuta e rarahaneng ea 3D ka nepo le lintlha tse ngata tse sa lebelloang. Mehlala ena ea dijithale e ka fetoloa ho ba li-prototypes tsa 'mele ho sebelisa theknoloji ea khatiso ea 3D, e hahang mabenyane ka lera ho sebelisa lisebelisoa tse fapaneng, ho kenyeletsoa boka ba ho lahla.

Tšebeliso ea khatiso ea 3D ka ho etsa mabenyane a khauta e bula menyetla e mecha ea ho theha meralo e rarahaneng haholo le e ikhethileng eo pele e neng e sa khonehe ka mekhoa ea khale ea ho etsa lintho. Theknoloji e boetse e nolofatsa ts'ebetso ea prototyping le tlhahiso, ho fokotsa linako tsa lead le ho nolofalletsa meralo ea mabenyane ka potlako.

Ho feta moo, tsoelo-pele ea theknoloji ea metallurgical le alloying e nolofalitse nts'etsopele ea li-alloys tse ncha tsa khauta tse nang le thepa e ntlafetseng joalo ka matla a eketsehileng, ho tšoarella le liphetoho tsa mebala. Li-alloys tsena tse ncha li holisa menyetla ea boqapi bakeng sa baqapi le bahlahisi ba mabenyane, li ba lumella ho sutumelletsa meeli ea mabenyane a khale a khauta.

Bokamoso ba theknoloji ea ho roala mabenyane a khauta

Ha theknoloji e ntse e tsoela pele, bokamoso ba ho roala mabenyane a khauta bo na le menyetla e monate le ho feta. Litheknoloji tse ntseng li hlaha joalo ka tlhahiso ea tlatsetso le liroboto tse tsoetseng pele li lebelletsoe ho tsoela pele ho ntlafatsa ts'ebetso ea ho lahlela, ho tlisa maemo a macha a ho nepahala, ho sebetsa hantle le ho itlhophisa.

Ntle le moo, ho kopanya bohlale ba maiketsetso le li-algorithms tsa ho ithuta mochini ho moralo oa mabenyane le tlhahiso ea mosebetsi oa tlhahiso ho na le monyetla oa ho ntlafatsa ts'ebetso ea ho lahlela, ho fokotsa litšila tsa thepa, le ho ntlafatsa boleng ba kakaretso ea mabenyane a felileng.

Qetellong, tsoelo-pele ea theknoloji ea ho etsa mabenyane a khauta ke bopaki ba bohlale le boqapi ba litsebi tsa mesebetsi ea matsoho le litsebi ho theosa le nalane. Ho tloha mokhoeng oa khale oa ho lahleheloa ke boka ho ea ho mehlolo ea sejoale-joale ea moralo oa dijithale le khatiso ea 3D, bonono ba ho etsa khauta bo tsoela pele ho fetoha ho fihlela litlhoko tsa linako tse lulang li fetoha.

Ha re sheba bokamoso, ho hlakile hore ho kopanngoa ha mesebetsi ea matsoho le thekenoloji ea morao-rao e tla tsoela pele ho bōpa sebaka sa ho roala mabenyane a khauta, ho fana ka menyetla e sa feleng ea ho qapa, ho iketsetsa le boleng lefatšeng le letle la mabenyane.

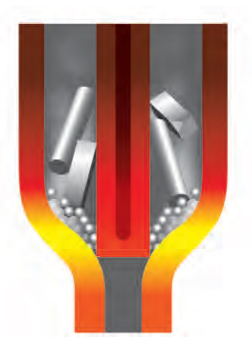

Lisebelisoa tsa mochini oa Vacuum Pressure:

1. Graphite crucible

2. Ceramic gasket

3. Baki ea ceramic

4. Sethibelo sa graphite

5. Thermocouple

6. Coil e futhumatsang

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur