Mochini oa ho Lahlela Mabenyane a Vacuum Pressure

Mochini oa ho Lahlela Mabenyane a Vacuum Pressure,

Mochini oa ho Lahlela Mabenyane a Vacuum Pressure,

Likaroloana

Mekhoa ea ho lahla

Mekhoa e tloaelehileng ea ho lahla ke:

ho akhela lelakabe

ho lahla

vacuum pressure die-cast

Lelakabe la mollo

Ho lahla lelakabe ke mokhoa o tloaelehileng ka ho fetisisa oa ho lahla 'me mohlomong ke oona o tloaelehileng ka ho fetisisa le o sa theko e tlaase. Mokhoa ona o bile molemo ho nts'etsapele mekhoa ea ho lahla empa ha e lumellane hantle le litlhoko tsa molao le tsa tekheniki tsa 'maraka oa kajeno. Thekniki ena e theilwe feela hodima bokgoni le bokgoni ba mosebeletsi: tshebediso ya thekeniki ena e hloka bokgoni ba ho laola lelakabe, tsebo e ntle ya ho sebetsa ka tshepe hammoho le kutlo le ho ba hlokolosi ha tshebetso.Le hoja e le nnete hore basebetsi ba bangata ke ditsebi tsa nnete tsa mokgwa ona re. nahana hore mokhoa ona o ke ke oa tiisa ho ikatisa le boemo ba boleng bo sa feleng. 'Me haeba ts'ebetso, e kang ena, e itšetlehile ka ho feletseng ho bokhoni le bokhoni ba mokhanni ha se mokhoa o feto-fetohang,' me ho feto-fetoha ha maemo ke ntho e hlokahalang bakeng sa lilaboratori tsa kajeno tsa litsebi tsa meno. Ts'ebetso e tlameha, ehlile, e ka hlahisoa hape ho sa natsoe bokhoni ba basebelisi. Ho phaella ho sena mokhoa oa ho lahla lelakabe ha o lumelle ho fana ka setifikeiti le litokomane tsa ts'ebetso ea ho lahla ka mekhoa ea ho laola mokhoa o itekanetseng.

Ho kenya letsoho

Induction casting e hlile e emetse katleho lefapheng la ho lahlela empa ho sa tsotellehe sena mokhoa ona o na le likarolo tse ling tse etsang hore ho se khonehe ho o sebelisa ka mokhoa o utloahalang le o hlophisitsoeng ka laboratoring ea setsebi sa meno.The induction system is semi-automatic in nature and the whole ts'ebetso, joalo ka ho akhela malakabe, e ipapisitse le bokhoni ba opareitara. sesebelisoa sa centrifugal. «Ka hona, ho ikatisa le boemo ba boleng bo sa feleng bo ke ke ba netefatsoa ho sebelisoa mokhoa ona.Ho lahlela ka mokhoa o potlakileng haholo. Motsoako oa tšepe o futhumatsa ho tloha ka hare ho ea ka ntle. Sebopeho sa theknoloji ea tsamaiso ea induction e etsa hore ho se ke ha khoneha ho tsitsisa mocheso oa alloy ka nako kapa ho thibela ho eketseha ha mocheso. Khatello ea centrifugal ke unidirectional 'me mechine e mengata ea ho kenya lisebelisoa ha e na tsamaiso ea vacuum, ka hona moea o fumanoang setsing o ka baka. ho lahla ha masoba.

Vacuum pressure die-casting

Vacuum pressure die casting e 'nile ea nkoa e le mokhoa oa boleng bo phahameng oa ho lahla, leha ho le joalo botumo ba eona bo ile ba lula bo lekanyelitsoe ho fihlela bohareng ba lilemo tsa bo-90 ka lebaka la hore mocheso o fihletsoeng ke lisebelisoa tsena o ne o sa tšoanelehe bakeng sa ho qhibiliha le ho lahlela lisebelisoa tse ncha tsa meno. Ho ile ha hlahisoa moloko o mocha oa lisebelisoa, o neng o khona ho qhibilihisa tšepe ea motheo, ea boleng bo holimo, ea Palladian le ea meno a bohlokoa.

Mechini e fehlang khatello ea Hasung vacuum e na le taolo e ntle haholo ea mocheso o qhibilihang, e hlahisa ho lahlela ka har'a vacuum le ho etsa hore ho khonehe ho etsa khatello e fapaneng. Sena sohle se tiisa ts'ebeliso e bonolo, ho ikatisa le boleng bo sa feleng mme se fokotsa tšusumetso ea opareitara sephethong.

Mokhoa oa ho fumana tlhahiso e ntle

Latela litlhoko tsa mocheso oa ho lahlela

Ho boloka taolo holim'a mocheso oa ho lahla ke tlhokahalo ea bohlokoa ka ho fetisisa ea ho boloka likarolo tsa metallurgic tsa alloy. Ho lumellana le lintlha tsa ho lahlela le lintlha tse itseng ho bohlokoa ho qoba ho fokotseha ha litšepe tse tlase tse qhibilihang tse teng ka har'a motsoako.

Tšepe e qhibilihisitsoeng ka mocheso o nepahetseng e tla ba le likarolo tsohle tse behiloeng ke k'hamphani ea tlhahiso, ho seng joalo ho ka 'na ha e-ba le liphetoho tse itseng mohahong oa metallurgic oa tšepe o ka bakang liphetoho tsa thepa ea theknoloji le mathata nakong ea mekhahlelo e latelang ea ts'ebetso.

Ho lahla ka kgatello ya hohle

Li-alloys tsa meno li entsoe ka litšepe tse 'maloa tse fapaneng, e' ngoe le e 'ngoe e na le boima ba eona bo ikhethang. Ka ho sebelisa mekhoa ea ente ea centrifugal phello e tla ba khatello ea mono-directional moo litšepe tse nang le li-densities tse phahameng li hlahisoa ka cylinder pele ho tse nang le li-densities tse tlaase. Ho sebelisa mekhoa ea ho lahla khatello, tšepe e hlahisoa ka mokhoa o tsitsitseng ka har'a silinda 'me joale silinda e pepesehetse khatello ea omni-directional le e sa khaotseng e lumellang hore ho behoe tšepe hantle.

Vacuum casting

Ho finyella khanyetso e phahameng ea mechine le ho nepahala ho lahla ho tla etsoa sebakeng se se nang moea. Sena se etsa bonnete ba hore ha ho na porous alloy casting ka ho feletseng.

Melemo ea Hasung die-casting system

Ho lumellana le litekanyetso tse behiloeng tsa mocheso

Sena se ka etsahala ka lebaka la sistimi e kopanyang taolo ka microprocessor, thermocouple le logic ea taolo, e etsoang ka sistimi e rarahaneng ea elektronike e nang le pointer e khubelu ea infra-red.

Melemo: Ho nepahala ho hoholo tlhahisong ea li-alloy le ho boloka ho latela lintlha tsa metallurgic.

Khatello ea Omnidirectional holim'a tšepe

Khatello e iketsang e hlahisa junifomo esita le khatello holim'a silindara eohle. Ha ho na phello ea centrifugal ea litšepe tse qapang motsoako.

Melemo: Motsoako o phahameng oa alloy compactness, layering e betere, ho boloka thepa ea alloy (ha ho na tlhoko ea lisebelisoa tse eketsehileng tse tla sebelisoa bakeng sa liteishene le lisebelisoa tse ngata tse lahliloeng)

Ho qhibiliha ho etsoa sebakeng sa sepakapaka

Empa ho lahla ho etsoa sebakeng se se nang moea hobane mechine ea ho lahla ea TVC, pele e phethoha, e etsa mokhoa o ikemetseng oa tlhahiso ea moea.

Melemo: Ho nepahala ho hoholo, boleng bo holimo le ho boloka nako ha ho phethela mesebetsi.

Boemo bo phahameng ba ts'ebetso

Tšebeliso ea likarolo tsohle tsa laboratori hobane ha ho na motho ea kenang lipakeng.

Melemo: Tšebeliso ea likarolo tsohle tsa laboratori.

Boleng ba ho ikatisa

Ts'ebetso ena ke ea boiketsetso 'me ha e na thuso ea motho.

Melemo: Potoloho ea boiketsetso le ho se be teng ha motho ho kenella ho fana ka phello e phethahetseng ea ho ikatisa.

Tsamaiso e sebetsang hantle ea litšenyehelo

Kakaretso ea tsamaiso ea ts'ebetso e na le litšenyehelo tsa 100%: tšebeliso ea matla a motlakase e tlaase 'me lintho tse sebelisoang ha li theko e tlaase.

Melemo: katleho ea litšenyehelo.

Hobaneng U Khetha mochini oa Hasung Vacuum Pressure Casting?

Mechini ea Hasung vacuum Casting e bapisoa le lik'hamphani tse ling

1. Sebelisa lisebelisoa tse tsebahalang lefatšeng ka bophara tse theko e phahameng tse tsoang mose ho maoatle.

2. Mosebetsi o moholo oa ho etsa bonnete ba mechine ea boleng.

3. Boleng bo phahameng haholo ho feta bafani ba bang ba China.

4. Liphetho tse kholo tsa ho lahla tšepe.

5. Ka theknoloji e tsoetseng pele ea ho sisinyeha (ho ikhethela), ho etsa bonnete ba hore litšepe tse boreleli tse lahliloeng ke mechini ea khatello ea Hasung.

Mochini oa "vacuum vacuum" oa TVC o na le sistimi ea vibration e u lumellang hore u be le liphetho tse ntle tsa ho lahlela, haholo lihlahisoa tsa hau tse tšesaane, mabenyane a khauta a Karat.

Ka Mitsubishi PLC touch panel controller, e bonolo empa e sebetsa hantle haholo.

U ka etsa casting ka letsoho kapa ka ho iketsa ka botlalo.

U ka ipehela liparamente u le mong ho latela likarolo tsa lihlahisoa tsa hau.

U ka seta li-momeries tsa polokelo u le mong.

Mochini oa ho lahla o sebetsa Jeremane IGBT ho futhumatsa theknoloji, Jeremane Schneider electrics, Jeremane Omron, Japan Mitsubishi electrics, Japan Panasonic service drive, Japan SMC, joalo-joalo.

Sebelisa lisebelisoa tsa boleng bo holimo, boqapi bo botle.

Tekheniki Parameters

| Mohlala No. | HS-TVC1 | HS-TVC2 | HS-TVC4 | HS-TVC6 | HS-TVC8 |

| Palo ea li-volts | 220V mohato o le mong / 380V 3 mekhahlelo 50/60Hz | 380V 3 mekhahlelo, 50/60Hz | |||

| Phepelo ea motlakase | 5KW/8KW | 8KW | 15KW | ||

| Max Temp | 1500°C | ||||

| Nako ea ho qhibiliha | 8-15 mets. / 3-5 mets. | 3-5 mets. | 3-5 mets | 3-5 mets. | 4-6 mets. |

| Tšireletso ea Khase | Argon / naetrojene | ||||

| Khatello | 0.1-0.3Mpa (E ka fetoha) | ||||

| Ho Nepaha ha Nako | ±1°C | ||||

| Bokhoni (Khauta) | 1kg | 2kg | 4kg | 6kg | 8kg (Khauta) |

| Max. Boholo ba flask | 4″x10″ / 5″x12″ | 5″x12″/6.3″x12″ | 6.3"x12" | 8.6″x12″ / 10″x13″ | |

| Pumpu ea Vacuum | Pompo ea vacuum ea boleng bo holimo / pompo ea vacuum ea Jeremane, degree ea vacuum - 100KPA (ho ikhethela) | ||||

| Kopo | Khauta, K khauta, silevera, koporo le lisebelisoa tse ling | ||||

| Mokhoa oa ts'ebetso | Ts'ebetso ea senotlolo se le seng ho phethela ts'ebetso eohle, sistimi e se nang kelello ea POKA YOKE | ||||

| Mofuta o phodileng | Sehatsetsi (se rekisoang ka thoko) kapa Metsi a mathang | ||||

| Litekanyo | 680*880*1530mm | ||||

| Boima ba 'mele | hoo e ka bang. 150kg | hoo e ka bang. 150kg | hoo e ka bang. 160kg | hoo e ka bang. 180kg | hoo e ka bang. 250kg |

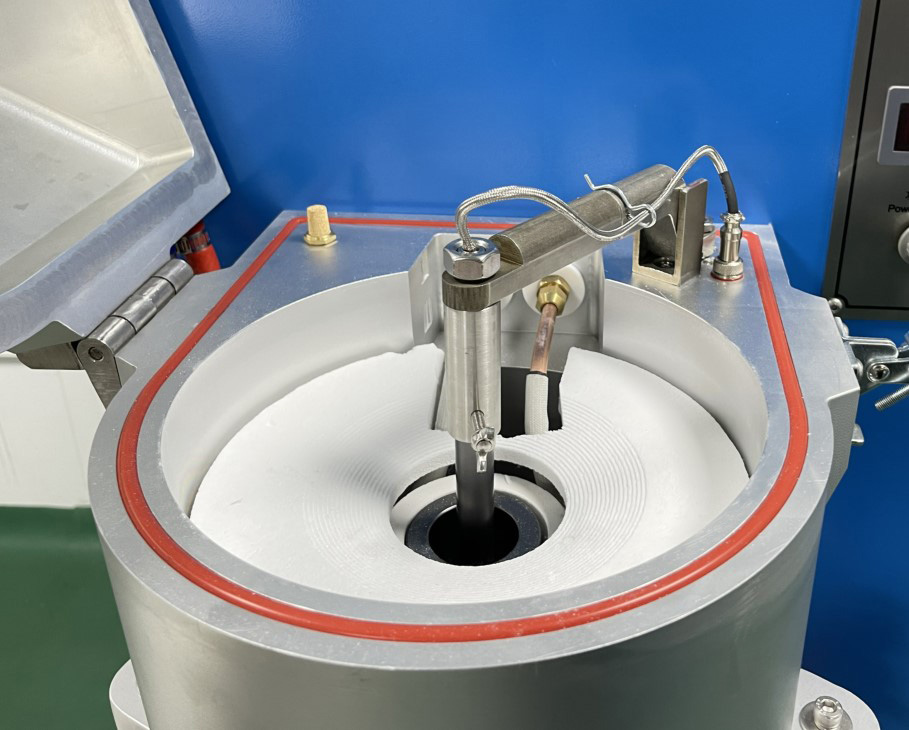

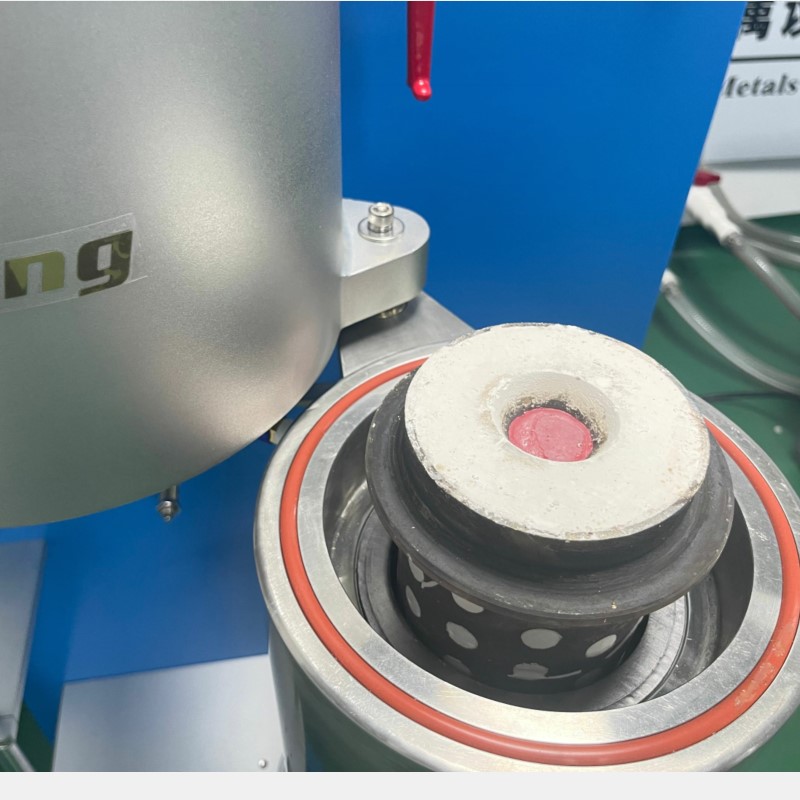

Pontšo ea Sehlahisoa

Hasung VC letoto la lisebelisoa tsa vacuum khatello ea mochini o fihla ho tloha ho tse nyane ho isa ho tse kholo, ho tloha lits'ebetsong tse ikemetseng ho isa tharollong ea tlhahiso ea othomathike ka botlalo. Likarolo tse ngata tse ikhethileng li u thusa ho ntlafatsa cast e 'ngoe le e' ngoe ho latela litšobotsi tsa eona. Ka kakaretso, molemong oa ho lahla mabenyane a silevera a khauta, matla a manyane a tsoa ho 1kg, 2kg, 3kg, 4kg ho fihla ho 8kg, ho isa ho matla a phahameng joalo ka 20kg kapa 30kg.

Lisebelisoa tsa mochini oa Vacuum Pressure:

1. Graphite crucible

2. Ceramic gasket

3. Baki ea ceramic

4. Sethibelo sa graphite

5. Thermocouple

6. Coil e futhumatsang

Mohala o felletseng oa tlhahiso ea mabenyane o kenyelletsa:

1. Mohatisi oa 3D

2. Vulcanizer

3. Ente ea boka

4. One e cheleng

5. Mochine oa ho lahla khatello ea vacuum

6. Ho hloekisa

7. Ho benya

Matsatsing ana, lifeme tsa mabenyane li rata ho ba le lits'ebetso tsa ho lahla ka boiketsetso tse bolokang litšenyehelo tse ngata tsa basebetsi le ho eketsa katleho ea tlhahiso. Ho Hasung, re u fa litharollo tse felletseng tsa ho roala mabenyane lihlahisoa tsa boleng bo holimo tse netefalitsoeng ho tsoa China.

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur