Metal Flakes Processing Machine Gold Flakes Ho Etsa Thepa ea ho Hloekisa Khauta

| Mohlala No. | HS-MS5 | HS-MS8 | HS-MS30 | HS-MS50 |

| Palo ea li-volts | 380V, 50/60Hz, mekhahlelo e 3 | |||

| Matla | 10KW | 15KW | 30KW / 50KW | |

| Mocheso o phahameng haholo. | 1500 ℃ | |||

| Bokhoni (khauta) | 1kg | 5kg | 30kg | 50kg |

| Kopo | khauta, silevera, koporo le lisebelisoa tse ling | |||

| Botenya ba maqephe | 0.1-0.5mm | |||

| Khase e sa sebetseng | Argon / naetrojene | |||

| Nako ea ho qhibiliha | 2-3 mets. | 3-5 mets. | 6-8 mets. | 15-25mins. |

| Molaoli | Taiwan Weinview/Siemens PLC Touch Panel Controller | |||

| Mofuta o phodileng | Sehatsetsi (se rekisoang ka thoko) kapa Metsi a mathang | |||

| Litekanyo | 1150x1080x1750mm | 1200x1100x1800mm | 1200x1100x1900mm | 1280x1200x1900mm |

| Boima ba 'mele | hoo e ka bang. 250kg | hoo e ka bang. 300kg | hoo e ka bang. 350kg | hoo e ka bang. 400kg |

Li-Flakes tsa Alloy tsa Khauta li felile

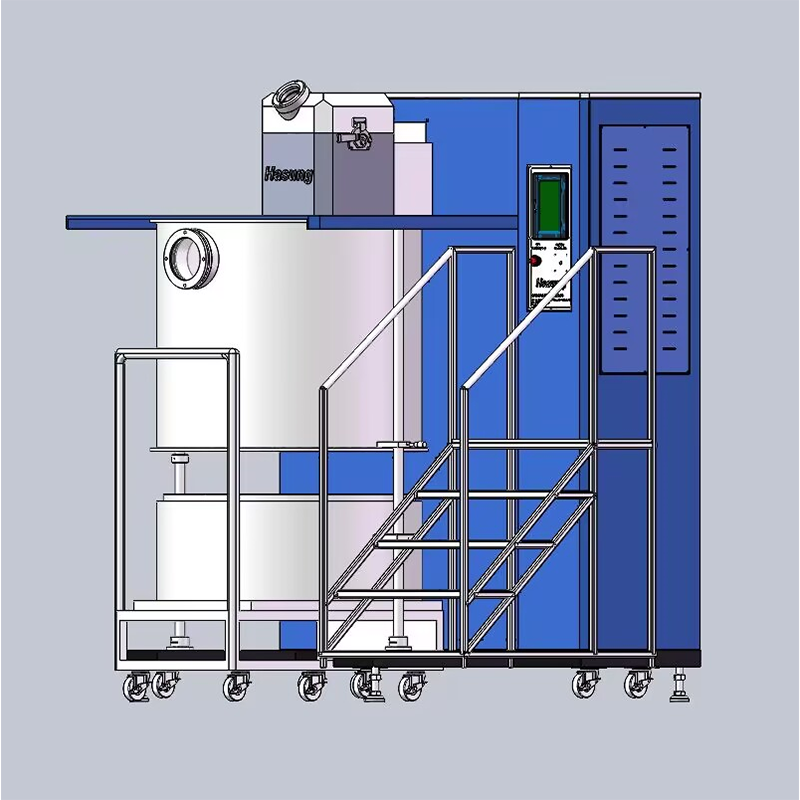

Kenyelletso ea Mochini oa Ho Etsa Lipholi tsa Khauta le Silver Alloy

A na u khoebong ea ho hloekisa khauta, silevera kapa platinum? A na u hloka mochine o ka tšeptjoang, o sebetsang hantle ho u thusa ho hlahisa lilakane tse tšesaane, tsa boleng bo holimo tse tsoang litšepe tsee tsa bohlokoa? Mechini ea rona ea morao-rao e entsoeng ka khauta le silevera ke khetho ea hau e ntle ka ho fetisisa. Sesebelisoa sena se entsoeng ka boqapi se etselitsoe ho qhibilihisa litšila tsa khauta, silevera le platinum ebe se li tšela holim'a diski ea centrifugal ho hlahisa li-flakes. Hore na o setsebi sa mabenyane, moetsi oa tšepe kapa mong'a mochini o hloekisang, mochini ona ke sesebelisoa sa bohlokoa bakeng sa ts'ebetso ea hau.

Moko oa mechine ea rona ea ho etsa li-flake tsa khauta le silevera ke bokhoni ba ho qhibiliha le ho hloekisa khauta e sa hloekang, silevera le platinum ho etsa li-flakes tse hloekileng, tsa boleng bo phahameng. Mochine o sebelisa theknoloji e tsoetseng pele ea ho qhibiliha ho netefatsa hore tšepe e qhibiliha ka mocheso o nepahetseng, e leng se hlahisang mokhoa o hloekileng le o sebetsang oa ho hloekisa. Ka mor'a ho qhibiliha, tšepe e tšeloa holim'a diski ea centrifuge, moo e ohloang ka lebelo le phahameng ho etsa li-flakes tse tšesaane tse tšoanang. Ts'ebetso ena e tiisa hore li-flakes tse hlahisoang li na le boleng bo tsitsitseng le botenya, li finyella litekanyetso tse phahameng ka ho fetisisa tsa indasteri.

E 'ngoe ea likarolo tsa bohlokoa tsa mochini oa rona oa ho etsa li-flake tsa khauta le silevera ke moralo oa ona o bonolo ho o sebelisa. Re utloisisa bohlokoa ba katleho le boiketlo ba tšebeliso sebakeng sa tlhahiso, ke ka lebaka leo re netefatsang hore mechine ea rona e bonolo ho sebetsa le ho e boloka. Ka taolo e hlakileng le litaelo tse hlakileng, basebetsi ba hau ba ka khona ho tseba ts'ebetso ea mochini kapele, ba fokotsa nako ea ho theoha le ho eketsa tlhahiso. Ho phaella moo, mochine o hahiloe ka thepa e tšoarellang le likaroloana ho netefatsa ho tšepahala ha nako e telele le litlhoko tse fokolang tsa tlhokomelo.

Mmarakeng oa kajeno o nang le tlholisano e kholo, boleng ba sehlahisoa bo bohlokoa haholo. Ka mechini ea rona ea ho etsa li-flake tsa khauta le silevera, o ka lula o hlahisa li-flakes tsa boleng bo holimo tse fihlelang litlhoko tse nepahetseng tsa bareki ba hau. Hore na o etsa lipampiri tsa mabenyane, lisebelisoa tsa indasteri kapa merero ea matsete, mechini ea rona e fana ka liphetho tse holimo nako le nako. Taolo e nepahetseng ea ts'ebetso ea ho qhibiliha le ho ohla e tiisa hore li-flakes ha li na litšila le mefokolo, ho u fa monyetla oa tlhōlisano 'marakeng.

Ho feta moo, mechini ea rona ea ho etsa li-flake ea khauta le silevera e entsoe ho nahanoa ka polokeho. Re kenyelletsa likarolo tse tsoetseng pele tsa polokeho ho sireletsa basebelisi ba hau le ho boloka tikoloho ea ts'ebetso e bolokehileng. Ho tloha tsamaisong ea ho shebella mocheso ho ea ho mochine oa ho emisa ts'ohanyetso, karolo e 'ngoe le e' ngoe ea mochine e entsoe ka hloko ho beha bophelo bo botle ba basebetsi pele. Boitlamo bona ba polokeho ha bo sireletse basebetsi ba hau feela empa hape bo fokotsa kotsi ea tšitiso ea tlhahiso ka lebaka la likotsi kapa ho robeha.

Ntle le ts'ebetso e ntle haholo le likarolo tsa polokeho, mechini ea rona ea ho etsa li-flake tsa khauta le silevera e sebetsa hantle haholo. Mochine o ntlafalitsoe ho fokotsa tšebeliso ea matla le litšila, o kenya letsoho ho boloka litšenyehelo le ho boloka tikoloho. Ka ho ntlafatsa ts'ebetso ea ho hloekisa le ho eketsa tlhahiso ea li-flakes tsa boleng bo phahameng, mechine ea rona e u thusa ho sebetsa ka mokhoa o atlehileng le o nang le boikarabelo. Ts'ebetso ena ha e ruise molemo oa hau feela, e boetse e ntlafatsa botumo ba hau joalo ka khoebo e hlokolosi, e nahanang pele.

Ha u tsetela mecheng ea rona ea ho etsa li-flake tsa khauta le silevera, ha u reke sekhechana sa thepa feela, empa hape u fumana molekane ea tšepahalang oa khoebo. Sehlopha sa rona sa ts'ehetso sa profeshenale se ikemiselitse ho etsa bonnete ba hore u fumana molemo o moholo holima letsete la hau. Ho tloha ho ho kenya le ho koetlisa ho ea ho thuso e tsoelang pele ea tekheniki, re mona ho u tšehetsa. Re utloisisa litlhoko tse ikhethang tsa indasteri ea hau mme re ikemiselitse ho fana ka litharollo tse lokiselitsoeng ho u thusa ho atleha.

Ka kakaretso, mechine ea rona ea ho etsa li-flake tsa khauta le silevera ke phetoho bakeng sa likhoebo tse amehang ho hloekisoeng ha khauta, silevera le platinum. Theknoloji ea eona e tsoetseng pele, moralo o bonolo oa basebelisi, boleng bo holimo, likarolo tsa polokeho le katleho li e etsa khetho e nepahetseng bakeng sa ba batlang se molemohali. Ka mochini ona e le karolo ea ts'ebetso ea hau, o ka ntlafatsa boleng ba sehlahisoa, oa eketsa ts'ebetso, 'me oa boloka basebetsi ba hau ba bolokehile. Etsa khetho e bohlale bakeng sa khoebo ea hau kajeno 'me u tsetele mochining oa ho etsa li-flake tsa khauta le silevera.

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur