Mechini e Hloekisang Khauta: Mechini eo ea bohlokoa ts'ebetsong ea tlhoekiso ea khauta

Khauta e 'nile ea e-ba letšoao la leruo le katleho ka lilemo tse makholo,' me boleng ba eona bo entse hore e be ntho e batloang likarolong tsohle tsa bophelo. Tshebetso ya ho hlwekisa kgauta e bohlokwa ho netefatsa bohlweki le boleng ba yona, mme dihlwekisi tsa kgauta di na le karolo ya bohlokwa tabeng ena. E le ho phethahatsa mokhoa o rarahaneng oa ho hloekisa khauta, ho hlokahala mechine e mengata ho netefatsa katleho le ho nepahala ha mokhoa oa ho hloekisa. Sengoliloeng sena, re tla kenyelletsa lisebelisoa tsa mantlha tse hlokehang setsing sa tlhoekiso sa khauta, ho kenyeletsoa mechini e etsang li-flake tsa khauta, liathomo tsa phofo ea khauta, lisebelisoa tsa tlhoekiso ea khauta, libopi tsa ho qhibilihisa khauta, granulator ea tšepe le vacuum casting ea khauta, mochini oa setempe sa logo, jj.

Mochini oa ho etsa li-flakes tsa khauta:

Bohato ba pele ba ho hloekisoa ha khauta ke ho fumana khauta ka sebōpeho sa eona se tala, hangata ka sebōpeho sa majoe a khauta kapa likotoana tsa khauta. E le ho qala ts'ebetso ea ho hloekisa, khauta e lokela ho aroloa hore e be li-flakes tse tšesaane, likotoana tse laolehang haholoanyane. Mona ke moo moetsi oa sequin a kenang teng. 'me ho bonolo bakeng sa morero oa ho noa lik'hemik'hale. Mochini o etselitsoe ho qhibiliha le ho fumana thepa ea khauta e tala hore e be li-flakes tse tšesaane tsa alloy tsa khauta, ho etsa li-flakes tsa khauta tse ka sebetsoang hape ka mokhoa oa tlhoekiso.

Atomizer ea phofo ea khauta:

Ntle le li-flakes tsa khauta, khetho e 'ngoe ke ho fetola thepa e tala hore e be phofo ea khauta. Atomizer ea phofo ea khauta ke sesebelisoa sa bohlokoa ts'ebetsong ena, e na le boikarabello ba ho fetola lisebelisoa tsa alloy ea khauta hore e be phofo (hangata 100 mesh size) ka ts'ebetso ea atomization. Sena se akarelletsa ho ntša khauta e qhibilihisitsoeng ka phaposing moo e tieang hore e be likaroloana tse nyenyane, ho hlahisa phofo ea khauta ea boleng bo holimo e leng bohlokoa mothating o latelang oa ho hloekisoa.

Sistimi ea ho hloekisa khauta:

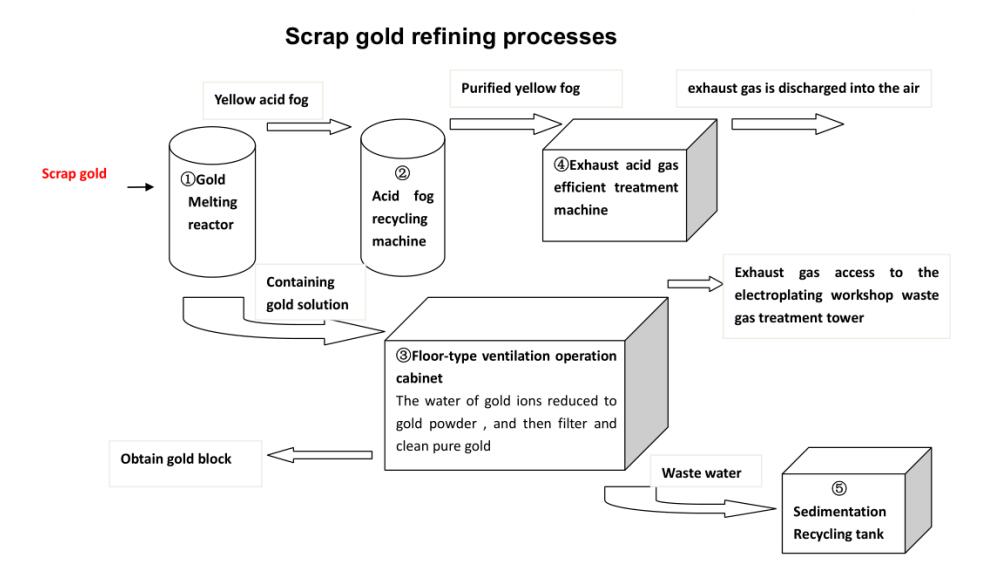

Bohareng ba sehloekisi leha e le sefe sa khauta ke mokhoa oa ho hloekisa khauta, o ikarabellang bakeng sa ho hloekisa khauta le ho tlosa litšila leha e le life kapa litšila. Sistimi ena hangata e na le likarolo tse fapaneng, ho kenyeletsoa litanka tsa lik'hemik'hale, lifilthara le lisebelisoa tsa sedimentation, tseo kaofela li sebetsang 'moho ho arola khauta e hloekileng ho litšepe tse ling le litšila. Lisebelisoa tsa ho hloekisa li sebelisa mekhoa ea lik'hemik'hale tse kang aqua regia kapa electrolysis ho finyella bohloeki ba khauta bo hlokahalang, ho netefatsa hore e finyella litekanyetso tsa indasteri bakeng sa tšebeliso ea khoebo. Hangata theko ea mohala oa tlhahiso e itšetlehile ka bokhoni ba kopo ea letsatsi le letsatsi, tsamaiso e tla etsoa le ho hlomelloa ka matla a kopiloeng. Sistimi ena ea tlhoekiso ea khauta haholo-holo e kenyelletsa sistimi ea karabelo ea lik'hemik'hale, sistimi ea karohano, sistimi ea likhoerekhoere tsa likhoerekhoere, lits'ebetso tsa ho hloekisa likotopo le mosi, joalo-joalo.

Sebōpi se qhibilihang sa khauta:

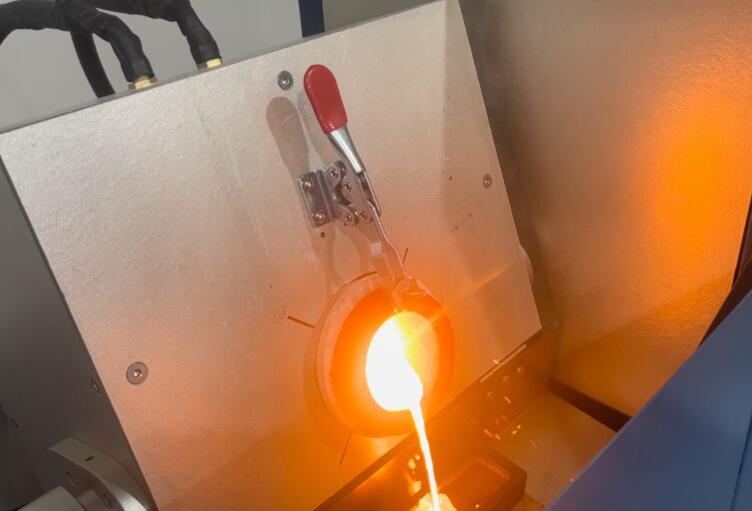

E le ho tsoela pele ho sebetsana le khauta ea seponche ho tloha ho e hloekisang khauta, seponche sa khauta se tlameha ho qhibiliha hore e be boemo bo qhibilihisitsoeng. Mona ke moo sebōpi sa khauta se kenang teng. Sebōpi se etselitsoe ho futhumatsa khauta sebakeng sa eona sa ho qhibiliha, ho etsa hore ho be bonolo ho sebetsana le ho arola litšila leha e le life tse setseng. Joale khauta e qhibilihisitsoeng e ka tšeloa ka har'a hlobo ho etsa litšepe tsa khauta kapa mefuta e meng e hlokahalang bakeng sa merero ea khoebo.

Metal granulating mochini:

E le hore u fumane lithunya tsa khauta tse tšoanang tse bonolo le tse nepahetseng tse lekantsoeng ka sekala sa ho bekha le boima ba ho qetela bo nepahetseng ba merero ea mekoallo ea khauta, granulator ea tšepe ke mochini oa bohlokoa oa ho nka karolo. Qhibiliha khauta 'me u fumane lithollo tsa khauta mochining oa granulating. E na le mefuta e 'meli ha e' ngoe e le mochini oa gravity granulating, e 'ngoe ke vacuum granulator.

Gold bar vacuum casting:

Ka mor'a hore khauta e hloekisoe 'me e qhibilihe e le lithunya tsa khauta, hangata e etsoa ka libopeho kapa mefuta e itseng ho etsa hore ho be bonolo ho e tšoara le ho e tsamaisa. Ho sebelisoa mochini oa khauta oa vacuum ho fihlela sena kaha o lahlela khauta e qhibilihisitsoeng ka nepo ka har'a hlobo tlas'a maemo a vacuum. Ts'ebetso ena e tiisa hore mekoallo ea khauta e thehoa ka mokhoa o nepahetseng le boleng bo phahameng, o itokiselitse litumellano tsa 'maraka.

Mochini oa khatiso oa logo o hatisang hydraulic:

Hangata barekisi ba khauta ba ka rata ho iketsetsa letšoao le mabitso a bona libareng tsa khauta, kahoo mochini oa setempe oa logo o etsa mosebetsi o tsoileng matsoho ho sena. Ka boholo bo fapaneng ba mekoallo le ho shoa ho fapaneng.

Sistimi ea ho tšoaea letheba:

Khauta hangata e na le nomoro ea eona ea serial joalo ka nomoro ea ID, kahoo hangata baetsi ba khauta ba sebelisa mokhoa oa ho tšoaea matheba ho ngola linomoro tsa serial ho engoe le e 'ngoe ea khauta.

Ka bokhutšoanyane, setsi sa tlhoekiso sa khauta se hloka letoto la mechine e khethehileng ho etsa tšebetso e rarahaneng ea ho hloekisa khauta. Ho tloha ho pshatla thepa ea khauta e tala hore e be li-flakes, ho e fetola phofo e ntle, 'me qetellong e hloekise le ho e lahlela sebopeho se lakatsehang, mochine o mong le o mong o bapala karolo ea bohlokoa ho netefatsa boleng le bohloeki ba khauta e hloekisitsoeng. Ka ho tsetela mecheng le lisebelisoa tse nepahetseng, lihloekisi tsa khauta li ka nolofatsa ts'ebetso le ho hlahisa lihlahisoa tsa khauta tsa boleng bo holimo tse fihlelang tlhoko ea 'maraka.

U ka ikopanya le Hasung bakeng sa lisebelisoa tsena kaofela bakeng sa khoebo ea hau ea khauta. U tla fumana mechini e ntle ka ho fetisisa e nang le moetsi oa mantlha ea nang le litheko le lits'ebeletso tse ntle.

Nako ea poso: May-21-2024