Powder Atomization Plants

Ho etsa Metal Powder

ThePoleMmokhoa oa etallurgy (PM) o etsa phofo ea tšepe.

Tšepeatomizer ea metsi a phofoe sebelisetsoa ho hlahisa lijo-thollo tse phahameng tsa boleng bo holimo le tse nang le homogenous le lithollo tsa alloy, hape le phofo, ho qala ka thepa e tala e qhibilihisitsoeng ka ho futhumatsa ka induction sebakeng se sireletsang, 'me joale Ha ho lahla phofo, ho tla amohela sethunya sa metsi se nang le khatello e phahameng ho pshatla. tšepe hore e be karoloana e ntles. Hangata, e sebelisoa indastering ea ho hloekisa tšepe.

The Gas Atomizer kee khetholloang ke tšilafalo e nyenyane ea tikoloho, tekanyo e phahameng ea phofo ea sebōpeho sa bolo, lintho tse fokolang tsa oksijene le lebelo la ho pholisa ka potlako joalo-joalo. Ka lilemo tse ngata tsa boqapi le ntlafatso e sa khaotseng, k'hamphani ea rona e ntlafalitse mokhoa oa rona oa ho etsa phofo ea atomization ea khase le theknoloji makhetlo a 'maloa e le ho hlahisa phofo ea tšepe le alloy ea ts'ebetso e phahameng. Hona joale, thekenoloji e fetohile eona ntho e ka sehloohong ea ho tšehetsa le ho khothalletsa lisebelisoa tsa ho etsa phofo ea atomization, lipatlisiso tse ncha le nts'etsopele ea theknoloji e ncha.

Molao-motheo oa ts'ebetso ea thepa ea atomizing e bolela mokhoa oa ho etsa phofo o qhibilihisang tšepe kapa motsoako tlas'a boemo bo itseng ka mokelikeli oa tšepe o tšeloa ka mokhoa o sa tsitsang ho boloka mocheso o phallang ka molomo oa ho kheloha ha metsi (ho ea tlase), 'me o nka monyetla oa likhase tse matla tsa nozzle. ho pshatla mokelikeli oa tšepe ka bongata bo botle le lerotholi le lenyenyane la metsi; Marotholi a mokelikeli o fofang a thatafala ho ba likaroloana tsa sebopeho sa bolo kapa tse nyane, 'me kahoo a phethela tšebetso eohle ea ho etsa phofo.Hangata, e sebelisoa indastering ea khatiso ea 3D ea tšepe.

-

Metal Flakes Processing Machine Gold Flakes Ho Etsa Thepa ea ho Hloekisa Khauta

Selelekela sa lisebelisoa:

1. Amohela induction ea maqhubu a mahareng, nako e khuts'oane ea ho qhibiliha le katleho e phahameng ea mosebetsi.

2. Kamore e qhibilihisang e sebetsa khase e inert e sebelisetsoang ho thibela oxidation ea lisebelisoa tsa tšepe le ho kenngoa ha litšila. Bakeng sa morero ona, e loketse lisebelisoa tsa tšepe tse hloekileng haholo kapa ho qhibiliha ho nang le likarolo tse nang le oxidized habonolo.

3. Mosebetsi o susumetsang oa mechine tlas'a boemo ba vacuum o amoheloa, 'me sebopeho sa' mala ha se arohane.

4. Ho qhibiliha ho sirelelitsoe ke khase ea inert e phahameng ea bohloeki, kahoo graphite ruthenium e na le tahlehelo e fokolang ea oxidation.

5. Ho sebelisa molaoli oa Taiwan Weinview / Siemens PLC, ts'ebetso e bonolo.

6. hlobo e futhumatsa ka boeona nakong ea ts'ebetso ea ho tšela ho netefatsa boleng ba ho lahla.

7. Ka likarolo tse ngata tse tummeng tsa lihlahisoa tsa lefats'e ho netefatsa boleng ba premium.8. Hangata e sebedisetswa ho hlwekisa kgauta.

-

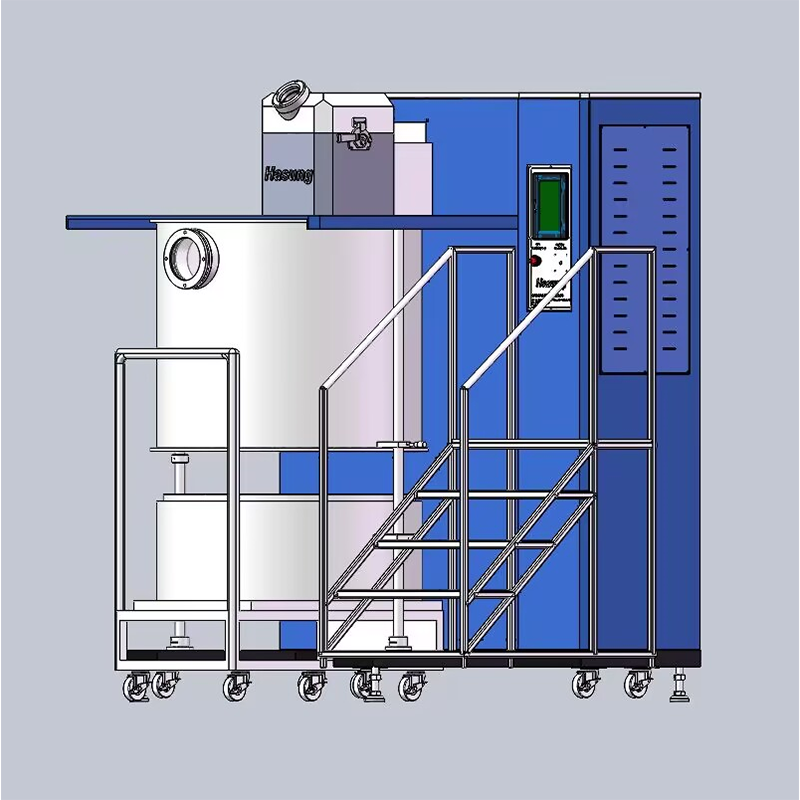

Atomizer ea Metsi ea Phofo ea Metal Bakeng sa Tšepe ea Bohlokoa ea Platinum Palladium

Litlhaloso tsa Sehlahisoa

Ho futhumatsa ka tlas'a tšireletso ea khase ea inert, ho sebelisa graphite crucible, mocheso o qhibilihisang ho fihlela ho likhato tse 1600. Mofuta oa mocheso o phahameng oa HT o ka sebelisoa, o sebelisa ceramic crucible (graphite susceptor), mocheso o qhibilihang o ka fihla likhato tse 2000. Mokhoa oa ho fana ka khase e chesang o ka eketsoa, moo khase e futhumatsoang ho likhato tse 500 bakeng sa ho etsa phofo e ntle ea tšepe. Thepa e hlahisa phofo ea tšepe e chitja e nang le mokelikeli o motle le boholo ba likaroloana tse pakeng tsa 10 le 200 microns, le ho feta ho fihla ho #400, 500 #. E ka sebelisoa lits'ebetsong tsa tlhahiso joalo ka laser selective sintering le metallurgy ea phofo.Melemo ea lisebelisoa tsa letoto la Hasung AU:

- Sebopeho se kopaneng le ts'ebetso e bonolo

- Tlhahiso e feto-fetohang le e sebetsang hantle ea lihlopha tse nyenyane tsa phofo ea tšepe

- Phetoho e bonolo le e potlakileng ea alloy le phetisetso ea nozzle

- Sekhahla se phahameng sa ho ntšoa ha phofo le sekhahla sa tahlehelo ea ho sila se tlase joalo ka 1/1000

- Ts'ebetso e tsitsitseng ea tlhahisoLintlha tsa Bohlokoa tsa Lisebelisoa tsa Hasung AU Series:

- Graphite crucible e ka futhumatsoa ho fihlela ho likhato tse 2000 sebakeng se sireletsang sa khase

- Enjene ea induction e laoloang ke Microprocessor (400 volts, matla a mekhahlelo e 3)

- Ts'ebetso e ntle haholo ea ho kopanya tšepe ea metsi, e ka kopanyang le ho qhibilihisa litšepe tse fapaneng pele ho athomo ea khase

- Sebakeng sa khase e sireletsang, mokhoa oa ho fepa o ka eketsoa ho fetola motsoako oa alloy

- Taolo e nepahetseng ea mocheso o sebelisa li-thermocouples tsa mofuta oa N-mofuta oa S

- Matla a crucible 1500cm3, 3000cm3 le 12000cm3 ka boikhethelo

- Sebelisa argon kapa naetrojene ho fihla ho li-atmosphere tse 30

- Sesebelisoa sa ho futhumatsa khase se ka eketsoa ho futhumatsa khase ho likhato tse 500 bakeng sa tlhahiso ea phofo e nang le likaroloana tse nyane.

- Ho fetola ka potlako le ho bonolo pakeng tsa mekhoa e 'meli ea ho sila bakeng sa tlhahiso e sebetsang ea li-powders tsa boholo bo fapaneng ba likaroloana

- Mokhoa o ntlafalitsoeng oa phallo ea moea ho qoba likaroloana tsa sathelaete bakeng sa phallo e ntle ea phofo

- Pokello ea phofo ea tšepe e omeletseng ka har'a tora ea lerōle tlas'a khase e sireletsang

- Pokello ea likotlo ka filthara ea moea

- E ka boloka li-parameter tse fetang 100

- Sesebelisoa se ka sebetsoa u le hole ka yuniti ea GSM -

100 mesh - 400 mesh Metal Powder Metsi Atomizer Machine

Haholo-holo e loketse ho etsa lisebelisoa tsa phofo (kapa granular) ka tanka ea atomizing ka mor'a ho qhibiliha ha tšepe kapa li-alloys tsa tšepe (ho ka sebelisoa ho qhibiliha ho tloaelehileng kapa ho qhibiliha ha vacuum). Haholo-holo e sebelisoang liunivesithing, litsi tsa lipatlisiso tsa saense, joalo-joalo Metal atomization phofo e ka hlahisoa ke metsi a phahameng a khatello ea atomization ho latela kopo ea phofo.

Thepa ena e boetse e loketse ho hlahisa le ho etsa lipatlisiso tsa tlhahiso ea tlatsetso (khauta e hloekisang) ho lokisetsa phofo ea tšepe liunivesithing le litsi tsa lipatlisiso tsa saense.

Thepa e boetse e loketse ho etsa lipatlisiso le tlhahiso ea mefuta e sa tšoaneng ea tšepe e sa hloekang, tšepe ea alloy, phofo ea koporo, phofo ea aluminium, phofo ea silevera, phofo ea ceramic le phofo ea brazing.