Lihlahisoa

-

Mochini o Tsoelang Pele oa ho Lahlela bakeng sa Khauta ea Silver Copper Alloy 20kg 30kg 50kg 100kg

1.Hang ha silevera ea khauta hlobolisa terata molamu oa tubemochini o tsoelang pele oa ho lahlabakeng sa mabenyane a ile a qalisoa 'marakeng, e ile ea fumana maikutlo a nepahetseng ho tsoa ho bareki ba bangata, ba ileng ba re mofuta ona oa sehlahisoa o ka rarolla litlhoko tsa bona ka katleho.Ho feta moo, sehlahisoa se sebelisoa haholo ho Metal Casting.

2.Mochine o Tsoelang Pele oa ho Lahlela bakeng sa ho Etsa Pipe ea Rod Strip e nang le 20kg 30kg 50kg 100kg ha e bapisoa le lihlahisoa tse tšoanang 'marakeng, e na le melemo e ikhethang e ke keng ea bapisoa mabapi le ts'ebetso, boleng, ponahalo, joalo-joalo,' me e thabela botumo bo botle 'marakeng.Hasung e akaretsa mefokolo ea lihlahisoa tse fetileng, 'me e tsoela pele ho li ntlafatsa. Litlhaloso tsa Mochini o Tsoelang Pele oa ho Lahlela bakeng sa ho Etsa Pipe ea Strip ea 20kg 30kg 50kg 100kg e ka etsoa ho latela litlhoko tsa hau.

-

Metal Flakes Processing Machine Gold Flakes Ho Etsa Thepa ea ho Hloekisa Khauta

Selelekela sa lisebelisoa:

1. Amohela induction ea maqhubu a mahareng, nako e khuts'oane ea ho qhibiliha le katleho e phahameng ea mosebetsi.

2. Kamore e qhibilihisang e sebetsa khase e inert e sebelisetsoang ho thibela oxidation ea lisebelisoa tsa tšepe le ho kenngoa ha litšila. Bakeng sa morero ona, e loketse lisebelisoa tsa tšepe tse hloekileng haholo kapa ho qhibiliha ho nang le likarolo tse nang le oxidized habonolo.

3. Mosebetsi o susumetsang oa mechine tlas'a boemo ba vacuum o amoheloa, 'me sebopeho sa' mala ha se arohane.

4. Ho qhibiliha ho sirelelitsoe ke khase ea inert e phahameng ea bohloeki, kahoo graphite ruthenium e na le tahlehelo e fokolang ea oxidation.

5. Ho sebelisa molaoli oa Taiwan Weinview / Siemens PLC, ts'ebetso e bonolo.

6. hlobo e futhumatsa ka boeona nakong ea ts'ebetso ea ho tšela ho netefatsa boleng ba ho lahla.

7. Ka likarolo tse ngata tse tummeng tsa lihlahisoa tsa lefats'e ho netefatsa boleng ba premium.8. Hangata e sebedisetswa ho hlwekisa kgauta.

-

Rotary Vacuum Induction Melting Furnace (VIM) FIM/FPt (Platinum, Palladium Rhodium le Alloys)

FIM/FPt ke sebopi sa vacuum bakeng sa ho qhibiliha platinum, palladium, rhodium, tšepe, le li-alloys tse phahameng tsa mocheso tse nang le mochini oa ho tilting.

E ka sebelisoa ho fumana ho qhibiliha ho phethahetseng ha li-alloys tsa platinum le palladium ntle le ho kenyelletsoa ha khase.

E ka qhibiliha ho tloha ho bonyane ba 500g ho ea ho boholo ba 10kg ea Platinum ka metsotso.

The melting unit e entsoe ka khese ea tšepe e pholileng ea metsi moo mokotla o nang le crucible rotate le hlobo ea ingot bakeng sa ho tebisa.

Mokhahlelo oa ho qhibiliha, oa homogenization le oa ho lahlela o ka etsahala tlas'a vacuum kapa sebakeng se sireletsang.

Sebōpi se phethehile ka:

- pompo ea rotary vacuum ea mekhahlelo e 'meli ka bateng ea oli;

- Sensor e phahameng e nepahetseng ea khatello ea dijithale;

- Optical pyrometer bakeng sa taolo ea mocheso;

- Phetoho e phahameng ea boemo bo holimo ea vacuum ea dijithale bakeng sa ho bala vacuum + Pontšo.

Melemo

- Theknoloji ea ho qhibilihisa vacuum

- Sistimi ea ho thetheha ka letsoho / e iketsang

- Mocheso o phahameng oa ho qhibiliha

Theknoloji ea HasungMocheso o Holimo oa Vacuum Induction E qhibilihisang Sebopi sa Teko sa Vacuum Melting Furnace

Likarolo tsa Sehlahisoa

1. Lebelo la ho qhibiliha ka potlako, mocheso o ka fihla ka holimo ho 2200 ℃

2. Ka ts'ebetso ea mochine o susumetsang, thepa e tsosoa ka mokhoa o ts'oanang

3. E na le taolo e hlophisitsoeng ea mocheso, beha sebaka sa ho futhumatsa kapa se pholileng ho latela litlhoko tsa ts'ebetso ea hau, lisebelisoa li tla futhumatsa kapa li pholile ho latela ts'ebetso ena.

4. Ka sesebelisoa sa ho tšela, sampuli e entsoeng ka ho qhibilihisoa e ka tšeloa ka har'a hlobo e lokisitsoeng ea ingot, 'me sebopeho sa sampuli eo u se batlang se ka tšeloa.

5. E ka qhibiliha tlas'a maemo a sa tšoaneng a sepakapaka: ho qhibiliha moeeng, sepakapaka se sireletsang le maemo a phahameng a vacuum, reka mofuta o le mong oa thepa, hlokomela mesebetsi e sa tšoaneng; boloka litšenyehelo tsa hau ho isa bohōleng bo itseng.

6. Ka tsamaiso ea bobeli ea phepelo: E ka lemoha ho eketsa likarolo tse ling nakong ea ts'ebetso ea ho qhibiliha, e leng ho loketseng hore u lokise lisampole tse fapaneng.

7. 'Mele oa sebōpi kaofela ke tšepe e sa hloekang e nang le pholileng ea metsi ho netefatsa hore mocheso oa khetla o ka tlase ho 35 °C ho sireletsa polokeho ea hau.

-

Mochini o qhibilihang oa Tilting Induction For Gold Silver Copper 2kg 3kg 4kg 5kg 6kg

Moralo oa mokhoa ona oa ho qhibiliha o thethehileng o ipapisitse le litlhoko tsa 'nete tsa morero le ts'ebetso, ho sebelisoa theknoloji ea morao-rao ea theknoloji e phahameng. Tšireletseho e tiisitsoe.

1. Adopt Jeremane Theknoloji ea ho futhumatsa ea IGBT, ho latela mokhoa o itekanetseng oa ho latela maqhubu le theknoloji e mengata ea tšireletso, e ka qhibilihisang tšepe ka nako e khutšoanyane, e boloka matla le ho sebetsa ka katleho.

2. Ho sebelisa ts'ebetso ea motlakase ea motlakase, ha ho na khethollo ka 'mala.

3. E amohela mokhoa oa ho laola phoso (ba khahlanong le fool), oo ho leng bonolo ho o sebelisa.

4. Ho sebelisa mokhoa oa ho laola mocheso oa PID, mocheso o nepahetse haholoanyane (± 1 ° C) (ho ikhethela).

5. Thepa ea ho qhibilihisa ea HS-TFQ e etsoa ka boikemelo le ho etsoa ka lihlahisoa tse tsoetseng pele tsa theknoloji bakeng sa ho qhibilihisa le ho lahlela khauta, silevera, koporo, joalo-joalo.

Letoto la HS-TFQ le etselitsoe ho qhibilihisa platinum, palladium, Rhodium, khauta, silevera, koporo le lisebelisoa tse ling.

6. Thepa ena e sebelisa likarolo tse ngata tsa lihlahisoa tse tummeng tsa kantle ho naha.

7. E boloka ho futhumatsa ha e ntse e tšela metsi a tšepe boemong bo botle bo nolofalletsang basebelisi ho fumana boleng bo botle ba ho lahlela.

-

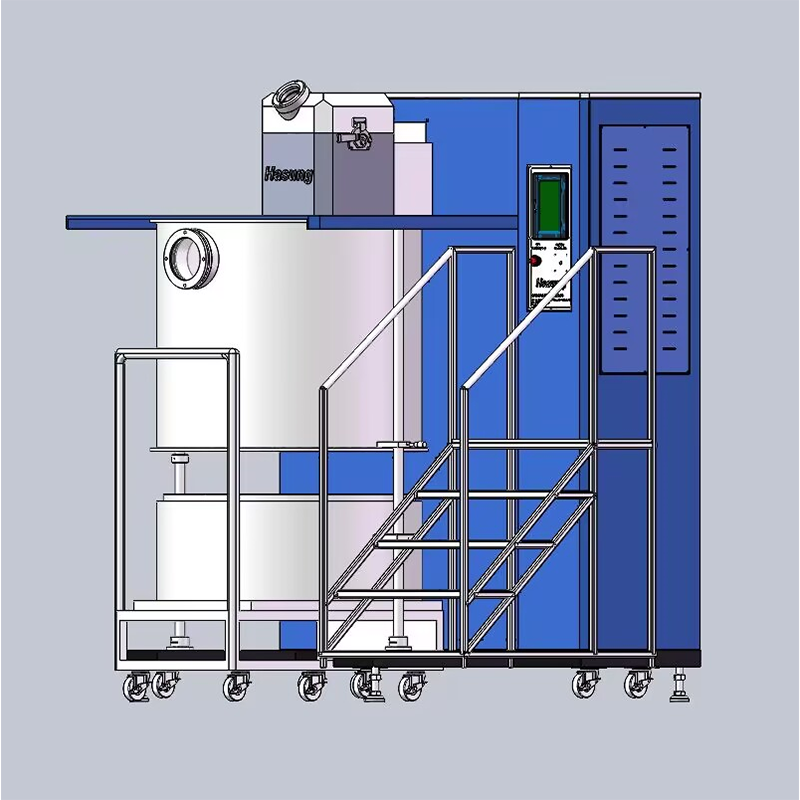

Smelt Oven Induction Speedy Melting 20kg 30kg 50kg 100kg Manual Tilting Gold Smelting Furnace

Ho Tilting Melting Furnaces bakeng sa ho qhibilihisa tšepe e ngata hore e be li-ingots kapa li-bullions.

Mechini ena e etselitsoe ho qhibilihisa bongata bo boholo, ho etsa mohlala fekthering ea ho sebelisa khauta bakeng sa matla a maholo a ho qhibiliha a 50kg kapa 100kg ka beche.

Letoto la Hasung TF - le lekoa le ho lekoa ho li-Foundries le lihlopha tsa bohlokoa tsa ho hloekisa tšepe.Libōpi tsa rona tsa ho qhibilihisa tse sekamang li sebelisoa haholo libakeng tse peli:

1. bakeng sa ho qhibilihisa litšepe tse ngata tse kang khauta, silevera kapa indasteri ea tšepe e entsoeng ka tšepe e kang ho lahlela masalla, 15KW, 30KW, le tlhahiso e phahameng ea 60KW le tokiso ea maqhubu a tlase e bolela ho qhibiliha ka potlako ho nang le liphello tse molemo ka ho fetisisa tse tsoang Chaena - esita le ka bongata bo boholo. – le e babatsehang ka ho kopanya.

2. bakeng sa ho lahlela likarolo tse kholo, tse boima ka mor'a ho kenya liindasteri tse ling.

Mehaho ea ho thetheha e sebetsang ka thata le e baballang chelete e ngata ho tloha TF1 ho ea ho TF15 e sebelisoa indastering ea mabenyane le litsing tsa tšepe tsa bohlokoa, ke lintlafatso tse ncha ka ho felletseng. Li na le lijenereithara tse ncha tse phahameng tsa ts'ebetso tse fihlang sebakeng sa ho qhibiliha ka potlako haholo 'me li netefatsa ho kopanya ka ho feletseng le ho homogenisation ea tšepe e qhibilihisitsoeng. Mefuta ea TF20 ho isa ho TF100, Ho ipapisitse le mohlala, matla a fapana ho tloha ho boima ba crucible ba 20kg ho isa ho 100kg bakeng sa khauta, haholo bakeng sa lik'hamphani tse etsang litšepe tsa bohlokoa.

The TFQ letoto la libopi le etselitsoe bakeng sa platinum le khauta, litšepe tsohle tse kang platinum, palladium, tšepe e sa hloekang, khauta, silevera, koporo, li-alloys joalo-joalo, li ka qhibiliha ka mochine o le mong ka ho fetola crucibles feela.

Libōpi tsa mofuta ona li ntle bakeng sa ho qhibiliha ha platinum, kahoo ha o tšela, mochine o boloka ho futhumala ho fihlela o batla o qeta ho tšela, ebe o tšela o koala ka boeona ha o se o felile.

-

Sebōpi se qhibilihang sa Induction bakeng sa Gold Platinum Silver Copper Rhodium Palladium

The MU melting unit system e ipapisitse le litlhoko tsa 'nete tsa ho qhibiliha ha mabenyane le morero oa ho hloekisa litšepe tsa bohlokoa.

1. Lisebelisoa tsa HS-MU tse qhibilihang li etsoa ka boikemelo le ho etsoa ka lihlahisoa tse tsoetseng pele tsa theknoloji bakeng sa ho qhibilihisa le ho lahlela khauta, silevera, koporo le lisebelisoa tse ling.

2. Lisebelisoa tsa HS-MUQ tse qhibilihisang li na le jenereithara e le 'ngoe ea ho futhumatsa empa li sebelisoa ka makhetlo a mabeli bakeng sa ho qhibiliha le ho lahlela platinum, palladium, tšepe e sa hloekang, khauta, silevera, koporo le li-alloys tse ling, tse ka sebelisoang ka ho fetola li-crucibles feela. Ho bonolo ebile ho loketse.

-

1kg 2kg Mini Induction Melting Furnace bakeng sa Koporo ea Khauta ea Silver

Sebōpi se qhibilihisang sa "desktop mini induction", matla ho tloha ho 1kg-2kg, e nkang metsotso e 1-2 ho qhibilihisa beche e le 'ngoe ea tšepe. E tla ka moralo o kopaneng 'me e ka nka lihora tse 24 e ntse e sebetsa. Hape, sebōpi sena sa tšepe se na le botsoalle bo botle ba tikoloho, se sebelisa matla a 6KW ka karolo e le 'ngoe ea 220V e bolokang matla a mangata ho fana ka liphello tse lakatsehang.

E khothaletsoa haholo bakeng sa fektheri e nyane ea mabenyane kapa workshop ea mabenyane, e sebetsang hantle le ea nako e telele ea ho sebelisa. Leha e le sesebelisoa se senyane, se etsa mosebetsi o motle ho basebelisi.

Sesebelisoa sa ho laola mocheso ke boikhethelo bakeng sa mochini ona.

-

Mochini o Ikemetseng oa Khauta oa Silver Bullion Vacuum 2KG

Ke Hobane'ng ha U Khetha HasungvacuumGold Bar Casting Machine ?

Mechini ea Hasung Vacuum Ingot Casting (HS-GV2) e etselitsoe ho etsa li-bullions tsa boleng ba 2kg tsa silevera le khauta. Mochini ona oa ho lahla o tla le mokhoa oa ho feto-fetoha ha hlobo ho etsa hore mekoallo ea hau ea silevera le khauta, li-ingots le li-bullion li be bonolo ka meralo le boholo ba hau.

Kamore ea khase e sa sebetseng ea mochini ona oa khauta oa silevera ea khauta e etsa bonnete ba hore u na le ho lahleloa ha ho qetela ka boleng ba boleng bo holimo le ponahalo ea seipone ka ho felisa ka ho felletseng mefuta eohle ea porosity, maqhubu a metsi kapa shrinkage likotong tsa hau tsa ho qetela.

Ho bapisa le mokhoa oa setso. Ts'ebetso eohle ea hau ea ho lahla e tla etsoa tlas'a vacuum le khase e inert. Ka hona, o fa lihlahisoa tsa hau tsa boleng bo holimo. Ka likarolo tse kaholimo, basebelisi ba hau ba netefalitsoe ka botlalo ho sebelisa lisebelisoa tsa rona habonolo.

Likarolo tsa mantlha tsa Hasung li tsoa lihlahisoa tse tsebahalang tsa malapeng le tse tsebahalang lefatšeng ka bophara joalo ka Japan AirTec, Taiwan Weinview, le Jeremane Siemens, Schneider, Omron, jj.

-

Mochini o Ikemetseng oa Khauta oa Bullion Vacuum 12KG 15KG 30KG

Ke Hobane'ng ha U Khetha HasungPhulaGold Bar Casting Machine ?

Hasung Vacuum Bullion Casting Machines e bapisoa le lik'hamphani tse ling

1. Ho fapane ho hoholo. vacuum ea lik'hamphani tse ling li laoloa ke nako. Ha se lefeela la sebele. Ba mpa ba e pompa ka tšoantšetso. Ha ba emisa ho pompa, ha se sebaka, ho tsoa habonolo. Ea rona e pompa ho fihla maemong a vacuum mme e ka boloka vacuum nako e telele.

2. Ka mantsoe a mang, seo ba nang le sona ke nako ea ho beha sekheo.

Ho etsa mohlala, ho kenya khase e inert ka mor'a motsotso o le mong kapa metsotsoana e 30 hoa iketsa. Haeba e sa fihle ho vacuum, e tla fetoloa ho khase e inert. Ke Ha e le hantle, khase ea inert le moea li fepeloa ka nako e le 'ngoe. Ho hang hase sekheo. Vacuum e ke ke ea bolokoa metsotso e 5. Hasung e ka boloka vacuum ka lihora tse fetang mashome a mabeli.

3. Ha re tshwane. Re ntšitse vacuum. Haeba o emisa pompo ea vacuum, e ntse e ka boloka vacuum. Ka nako e itseng, re tla fihlela sete Kamora ho beha boleng, e ka fetohela mohatong o latelang mme ea eketsa khase ea inert.

4. Likarolo tsa Hasung tsa mantlha ke lihlahisoa tse tsebahalang tse tsoang Japane, Fora le Jeremane.

-

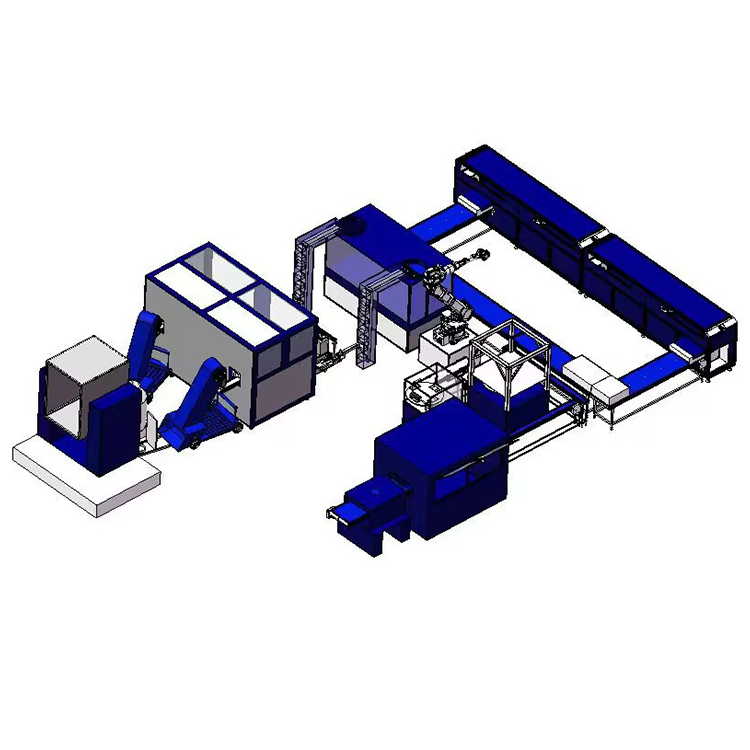

Tunnel Type Gold Ingot Vacuum Casting System

HS-VF260 ke sebopi sa kotopo ea induction eo, leha e kenyelletsa theknoloji e tsoetseng pele haholo, e tenyetsehang ebile e bonolo ho e sebelisa. E fumaneha ka mefuta e fapaneng, e 'ngoe le e' ngoe ea Tera Automation HS-VF260 e entsoe, ea laoloa le ho bokelloa ka har'a k'hamphani ea rona.

Sebōpi sa rona sa kotopo se arotsoe ka liphaposi tse tharo, moo lijo-thollo li qhibilihang sebakeng se laoloang 'me li lahleloa ka har'a li-ingots tse benyang le tse bataletseng ka ho feletseng tsa khauta kapa silevera. Theknoloji e nang le tokelo ea molao e bitsoang Pinch Valves, e behiloeng lipheletsong tse peli tsa kotopo, e tiisa ho tiisoa ka mokhoa o phethahetseng: ha e le hantle, tsamaiso ena e nang le li-valve tsa pneumatic e boloka oksijene ka ntle ho kotopo, ho boloka sepakapaka se sa sebetseng le ho fokotsa haholo khase - hangata naetrojene - e sebelisoang. . Lisebelisoa tsa graphite li nka nako e telele 'me ha li senyehe ka lebaka la oxidation.

Joalo ka libopi tse ling kaofela tsa induction casting, sebōpi sena se hloka ho hokahanngoa le setsi sa sehatsetsi sa metsi se boholo bo lekaneng.

-

TVC Series Induction Vacuum Pressure Casting Machine bakeng sa Khauta Silver Copper

Mochini o Felletseng oa Vacuum Pressure Casting o felletseng

Theknoloji e ncha ea ho ntlafatsa liphetho tsa tlhahiso

Sistimi ea Hasung Casting

1.Ho koala sekoahelo ka bohona, tsohle li sebetsa ka bohona bakeng sa ho lahla hangata ho ntlafatsa phallo ea thepa le ho tlatsa hlobo.

2.Castings e bonts'a tekano e phahameng le e tsitsitseng haholoanyane

3.Porosity e fokotsehile haholo

4. Mamella Max. Li-bars tse 4 tse behang khatello.

5. Sistimi ea ho itšeha ea SBS ntle le ho sebelisa li-gaskets, boloka litšenyehelo.

6.Castings e na le khatello e kholo ea khatello le thepa ea elasticity, e leng ho etsang hore ho be bonolo ho sebetsa ho ea pele.

7. Ts'ebetso e bonolo ea ho ama e nang le skrine ea bohlokoa ea parameter

8. Mananeo a 100 a teng.

-

VPC Series Vacuum Pressure Casting Machine bakeng sa Jewellery

Khatello holim'a Mechini ea Vacuum Casting

VCT ke lelapa la khatello holim'a mechini ea vacuum casting e etselitsoeng ho fihlela litlhoko tse matla haholo tlhahisong ea boka e lahlehileng ea khauta, K-khauta, koporo, boronse, lialloys. Hangata li sebelisoa mabapi le mochine oa khatiso oa 3d bakeng sa ho lahla ka ho toba ho fumana likarolo tsa pele tsa tšepe tsa lintho tse rarahaneng.

Lelapa lena la mechini le sebetsa ka mohopolo o mocha, oa phetoho ea kamore e habeli. Sistimi ena e ncha e fana ka melemo e mengata ha e bapisoa le mokhoa oa khale oa ho hula ka kamoreng e fumanehang hona joale 'marakeng.

Ho VCT, kamore e qhibilihang le kamore ea botlolo ha e na boikemelo ka ho felletseng: ha o ntse o lahla, mochini o ka laola ente ea tšepe ka har'a hlobo ka ho sebelisa khatello e fapaneng nakong ea ho tšela. Sena se fana ka ente e potlakileng ha e bapisoa le matla a khoheli a tšollang ka molemo oa ho lahlela lintho ka mocheso o tlase. Sena se tla fella ka ho phethoa hantle ha holim'a metsi le ho fokotsa ho fokotseha ha likarolo tse lahliloeng.Potoloho ea ho lahla e nka metsotso e seng mekae feela, 'me, ha botlolo e fetileng e ntse e pholile ka khase e sireletsang bakeng sa ho se be le oxidation, tefiso e latelang e ka kenngoa ka har'a crucible' me ea qhibiliha, kahoo e koahela lipotoloho tse peli ntle le tšenyo ea nako.

Mochini o ikemela ka botlalo, o na le sistimi ea ho shebella e thehiloeng ho PC bakeng sa ho fumana litekanyetso tsa ts'ebetso le taolo ea data ea tlhahiso, ka ho hlophisoa habonolo ha mananeo a ho lahla a loketseng mefuta e mengata ea alloy.

Mochini ona oa phetoho ke motsoako oa boenjiniere bo tsoetseng pele ka ho fetesisa le lilemo tsa boiphihlelo ba ho etsa lintho tse tla tlisoa ke Hasung feela fekthering ea hau.