Mechini ea ho khabisa ka hydraulicke lisebelisoa tsa bohlokoa bakeng sa ho etsa mekoallo ea khauta, lichelete tsa tšepe le setempe sa matšoao. Mechini ena e sebelisa khatello ea haeteroliki ho hatisa meralo le lipaterone tse rarahaneng holim'a mefuta e fapaneng ea tšepe, e li etsang hore e be tse loketseng ho hlahisa lihlahisoa tsa boleng bo holimo le tse khahlang pono. Ebang e sebelisetsoa ho hlahisa lichelete tsa tšepe tsa sehopotso, setempe sa letšoao la letšoao, kapa mekoallo ea khauta e entsoeng ka morero oa ho tsetela, mechini ea hydraulic embossing e bapala karolo ea bohlokoa ts'ebetsong ea tlhahiso. Sehloohong sena, re tla hlahloba bohlokoa ba mechini ea hydraulic embossing bakeng sa ho etsa mekoallo ea khauta e entsoeng, lichelete tsa tšepe le litempe tsa logo le mesebetsi ea tsona ea mantlha le lits'ebetso.

Ts'ebetso ea ho etsa mekoallo ea khauta, lichelete tsa tšepe le setempe sa logo e hloka ho nepahala le ho ela hloko lintlha, e leng moo metjhini ea hydraulic embossing e sebetsang hantle. Mechini ena e etselitsoe ho sebelisa khatello e laoloang ea hydraulic, e lumellang meralo e rarahaneng hore e hatisoe ka nepo holim'a tšepe. Ebang ke lintlha tse rarahaneng tsa chelete ea sehopotso kapa mongolo o nepahetseng oa lets'oao holim'a tšepe, mechini ea hydraulic embossing e netefatsa liphetho tse tsitsitseng, tsa boleng bo holimo.

E 'ngoe ea melemo ea mantlha ea mechini ea hydraulic embossing e sebelisoang ho theha mekoallo ea khauta e entsoeng, lichelete tsa tšepe le setempe sa logo ke bokhoni ba bona ba ho ikamahanya le lisebelisoa tse fapaneng tsa tšepe. Ebang ke khauta, silevera, koporo kapa litšepe tse ling tsa bohlokoa, mechini ena e ka hatisa meralo holim'a mefuta e fapaneng ea tšepe, ea etsa hore e feto-fetohe le maemo ho latela litlhoko tse fapaneng tsa tlhahiso. Ho feto-fetoha hona ho etsa hore ho be le mefuta e mengata e fapaneng ea litšepe tsa khauta tse entsoeng, lichelete tsa tšepe le li-logo tse hatisitsoeng ho fihlela litlhoko tse ikhethang tsa liindasteri le lits'ebetso tse fapaneng.

Ntle le ho feto-fetoha ha bona, mechine ea hydraulic embossing e fana ka taolo e nepahetseng ea mokhoa oa ho khabisa, ho etsa bonnete ba hore sehlahisoa sa ho qetela se kopana le boleng bo phahameng ka ho fetisisa le litekanyetso tsa mosebetsi. Khatello ea Hydraulic e ka fetoloa hore e lumellane le botenya ba tšepe bo fapaneng le botebo ba embossing, e leng se lumellang ho ikamahanya le maemo le ho feto-fetoha ha maemo ha ho etsoa tlhahiso. Boemo bona ba taolo bo bohlokoa bakeng sa ho theha mekoallo ea khauta e entsoeng, lichelete tsa tšepe le litempe tsa logo tse nang le meralo e rarahaneng le lintlha tse ntle, ho netefatsa hore sehlahisoa ka seng se kopana le lintlha tse hlokahalang.

Ho phaella moo, mechine ea hydraulic embossing e etselitsoe hore e be e tšoarellang le e ka tšeptjoang, e khonang ho finyella litlhoko tsa tlhahiso e phahameng ea tlhahiso le ts'ebetso e tsoelang pele. Ho tšepahala hona ho bohlokoa ho bahlahisi ba hlahisang mekoallo ea khauta e entsoeng, lichelete tsa tšepe le litempe tsa li-logo kaha li netefatsa boleng bo tsitsitseng le katleho tšebetsong ea tlhahiso. Mechini ena e na le meaho e matsutla-tsutla le litsamaiso tse tsoetseng pele tsa haeteroliki ho fana ka ts'ebetso e tšepahalang, e ba etsa thepa ea bohlokoa bakeng sa baetsi ba indasteri ea lichelete tsa tšepe le ea setempe.

Monyetla o mong oa bohlokoa oa mechini ea hydraulic embossing ke katleho ea ts'ebetso ea bona ea tlhahiso. Mechini ena e khona ho hatisa meralo ka potlako holim'a tšepe, e lumellang tlhahiso e phahameng haholo ea litšepe tsa khauta tse entsoeng, lichelete tsa tšepe le litempe tsa logo. Ts'ebetso ena e bohlokoa ho fihlela litlhoko tsa tlhahiso e kholo, e lumellang bahlahisi ho hlahisa lihlahisoa tse ngata ka nako e nyane. Ho sa tsotellehe hore na ho phethahatsa litaelo tsa lichelete tsa tšepe tsa sehopotso kapa ho hlahisa mekoallo ea khauta e entsoeng ka lebitso, mechine ea hydraulic embossing e ka tsamaisa mokhoa oa tlhahiso, kahoo e eketsa tlhahiso le phaello ka kakaretso.

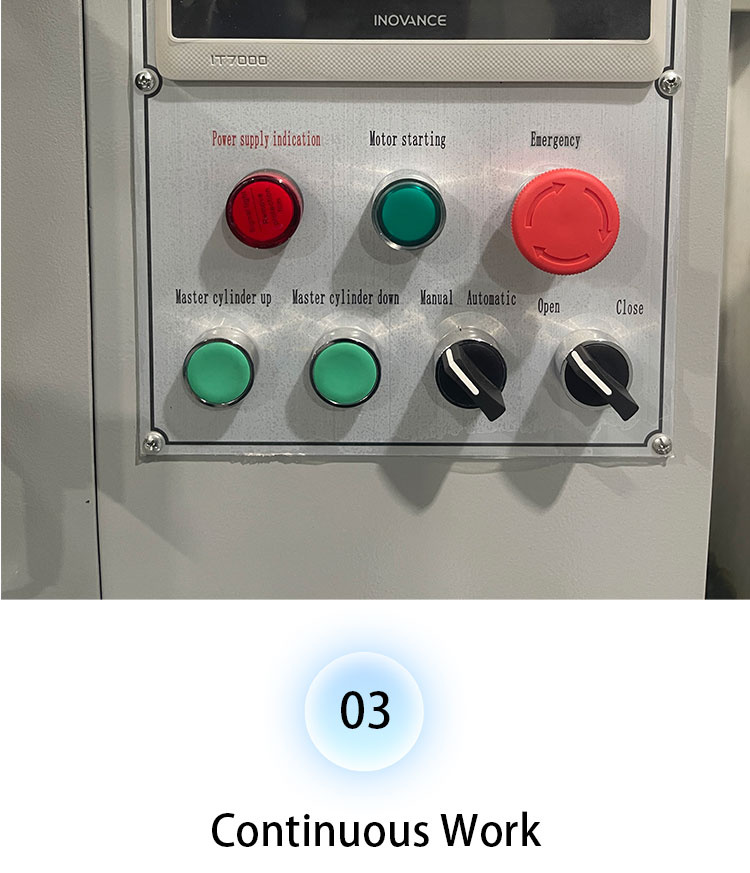

Ho feta moo, mechini ea hydraulic embossing e na le likarolo tse tsoetseng pele le mahlale a ntlafatsang ts'ebetso le ts'ebeliso ea tsona. Ho tloha lits'ebetsong tsa taolo ea dijithale bakeng sa taolo e nepahetseng ea khatello ho isa lits'ebetsong tsa ho hatisa ka boits'oaro, mechini ena e etselitsoe ho ntlafatsa ts'ebetso ea ho etsa litšepe tsa khauta tse entsoeng, lichelete tsa tšepe le setempe sa logo. Ho kopanngoa ha thekenoloji e tsoetseng pele ha ho ntlafatse feela ho nepahala le ho tsitsa, empa hape ho nolofatsa ts'ebetso ea mochine, ho etsa hore ho be bonolo ho mosebedisi le ho sebetsa hantle bakeng sa opereishene.

Ho feta moo, metjhini e kentsoeng ka li-hydraulic embossing e etselitsoe ho latela litekanyetso le melaoana ea boleng bo tiileng bakeng sa tlhahiso ea mekoallo ea khauta e entsoeng, lichelete tsa tšepe le litempe tsa logo. Ebang ke ho netefatsa ho nepahala ha meralo ea lichelete tsa tšepe kapa ho boloka botšepehi ba li-logos tsa brand, mechine ena e etselitsoe ho finyella litlhoko tse khethehileng tsa indasteri, ho netefatsa hore sehlahisoa sa ho qetela se finyella litekanyetso tse hlokahalang tsa bonnete le boleng. Ho ikamahanya le maemo a boleng ho bohlokoa bakeng sa bahlahisi ba indastering ea lichelete tsa tšepe le litempe kaha e fana ka kholiseho ho lihlahisoa tseo ba li hlahisang le ho netefatsa hore ho latela melaoana ea tsamaiso.

Ho feta moo, mechini ea hydraulic embossing e fana ka litharollo tse theko e tlase bakeng sa bahlahisi ba amehang tlhahisong ea litšepe tse entsoeng ka khauta, lichelete tsa tšepe le setempe sa logo. Ka ho nolofatsa mokhoa oa ho khabisa le ho ntlafatsa katleho ea tlhahiso, mechine ena e thusa ho fokotsa litšenyehelo tsa tlhahiso le ho ntlafatsa phaello e akaretsang. Bokhoni ba mechini ea hydraulic embossing e theko e tlase ho hlahisa liballo tsa khauta tse entsoeng ka boleng bo holimo, lichelete tsa tšepe le li-logos tse hatisitsoeng li etsa hore mechini ea hydraulic embossing e be letsete la bohlokoa bakeng sa bahlahisi ba batlang ho eketsa bokhoni ba tlhahiso ha ba ntse ba boloka moeli oa tlholisano 'marakeng.

Ka bokhutšoanyane, mechini ea hydraulic embossing e phetha karolo ea bohlokoa ts'ebetsong ea ho etsa litšepe tsa khauta tse entsoeng, lichelete tsa tšepe le litempe tsa logo ka ho nepahala, ho feto-fetoha ha maemo, ho tšepahala, katleho, theknoloji e tsoetseng pele, ho latela litekanyetso tsa boleng le ho boloka litšenyehelo. Mechini ena e bohlokoa bakeng sa ho theha lihlahisoa tsa boleng bo holimo le tse khahlang pono tse fihlelang litlhoko tse fapaneng tsa indasteri ea lichelete tsa tšepe le litempe. Mechini e khabisang ea Hydraulic e khona ho hatisa meralo e rarahaneng holim'a mefuta e fapaneng ea tšepe 'me e na le bokhoni ba ho hlahisa molumo o phahameng, e leng se etsang hore e be khetho ea bohlokoa bakeng sa bahlahisi ba batlang ho hlahisa mekoallo ea khauta e entsoeng, lichelete tsa tšepe le matšoao a setempe a boleng bo holimo le boqapi. thepa e sieo.

U ka ikopanya le Hasung bakeng sa bareng ea tšepe e etsang mohala oa tlhahiso ka ho

Whatsapp: 008617898439424

Email: sales@hasungmachinery.com

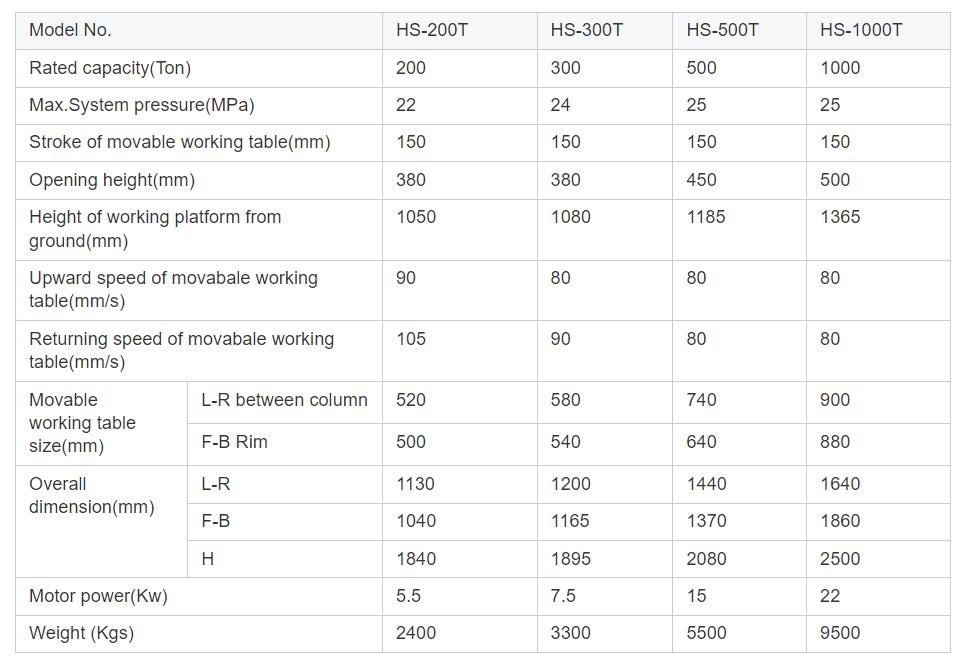

Lintlha tsa tekheniki:

Nako ea poso: May-31-2024