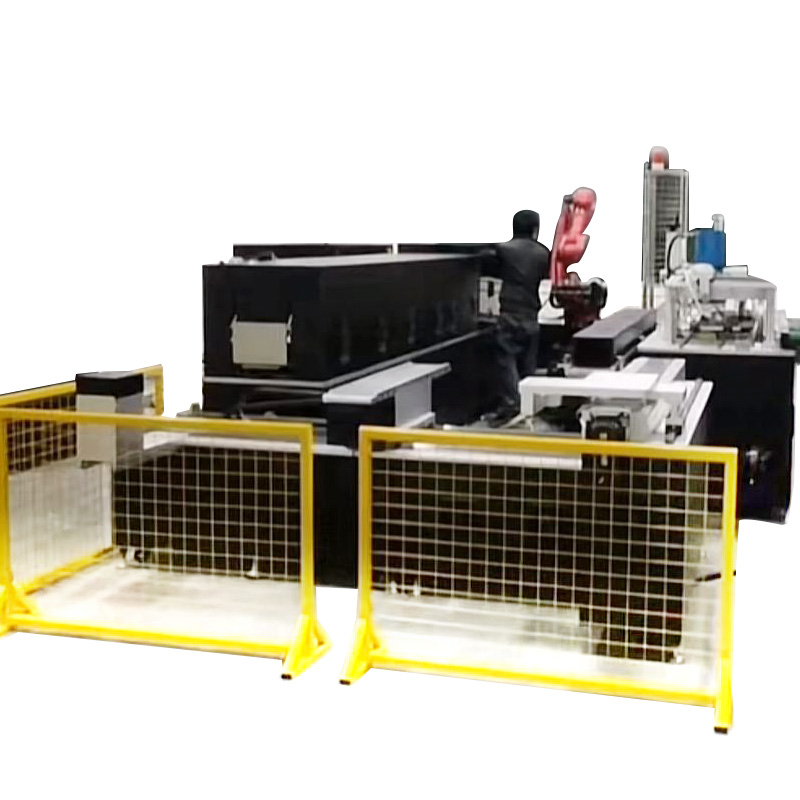

Tunnel Type Gold Ingot Vacuum Casting System

Tharollo e utloahalang

Lilemong tse fetileng, 'maraka oa matsete a tšepe a bohlokoa a ntse a eketseha le ho feta: mehleng ena ingot e tlameha ho ba le thepa e tšoanang ea botle ba lehakoe.

Ka ho sebelisa mechini e fumanehang 'marakeng pele ho qala HS-VF260, motho o ne a ka etsa lihlahisoa tsa boleng bo botle, empa ho ne ho le thata hore basebetsi ba li laole. Ha e le hantle, ho lekanyetsoa ha maemo a mosebetsi le tlhokomelo e tloaelehileng e ne e batla e lekanyelitsoe feela ho basebetsi ba hloahloa haholo.

Ho qalisoa ha HS-VF260 ho ile ha fetola tšimo: lik'hamphani lefats'eng lohle li ile tsa fanoa ka libono tsa likotopo tse lokiselitsoeng, tse ka senyehang ho ea ka mefuta ea tlhahiso (ingot ho tloha ho 1 ounces, ho fihlela ho 400 ounces kapa 1000 ounces), eo tlhokomelo ea eona e neng e fumaneha.

Tharollo e le 'ngoe feela e ne e le ho rala sebōpi sa kotopo sa induction se nang le sebopeho se bonolo le se bonolo sa mosebedisi (HMI touchscreen), se neng se ka qhaqholloa ka botlalo ka sepane se le seng feela.

Mathata a Bohlokoa le Mefokolo ea Tsamaiso ea Setso

Sebōpi se sebakeng se bulehileng 'me lelakabe le lula le tuka, ka hona likotsi tsa likotsi mosebetsing li phahame haholo.

Likotsi tse phahameng tsa tahlehelo ea tšepe.

Ho ntša mosi o moholo, oo ho hlaphoheloa ha oona ho theko e boima haholo bakeng sa k'hamphani, le nts'etsopele ea tšimo e matla ea motlakase.

Lintho tse ngata tse sebelisoang, tse kang li-crucibles, li sebelisoa 'me li felloa ke matla ka potlako, tse bolelang litšenyehelo tse phahameng tsa ts'ebetso.

Boleng ba ingot e phethiloeng (ho khanya, ho hloeka, ho bata) ke bohareng-bo phahameng.

Sebōpi se hloka boteng ba kamehla ba basebetsi.

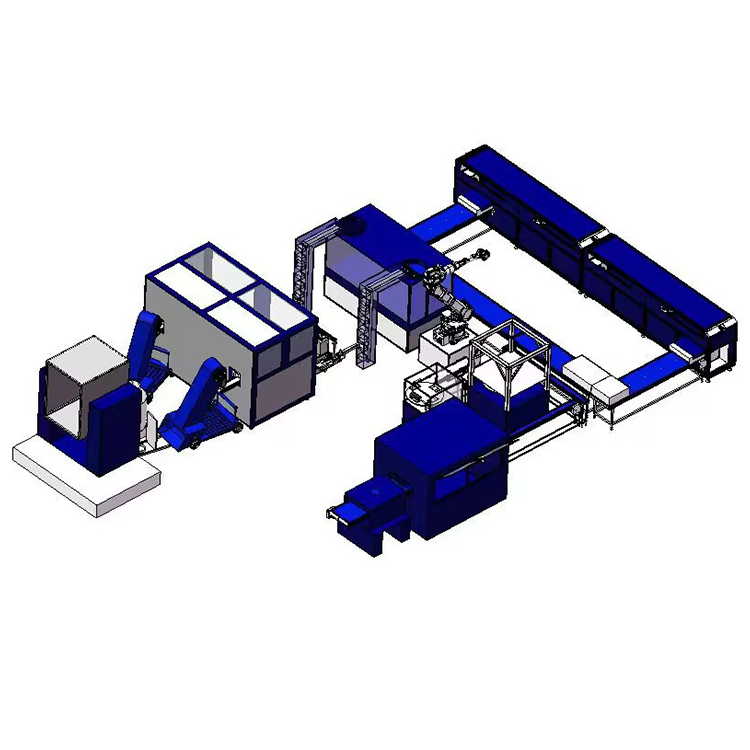

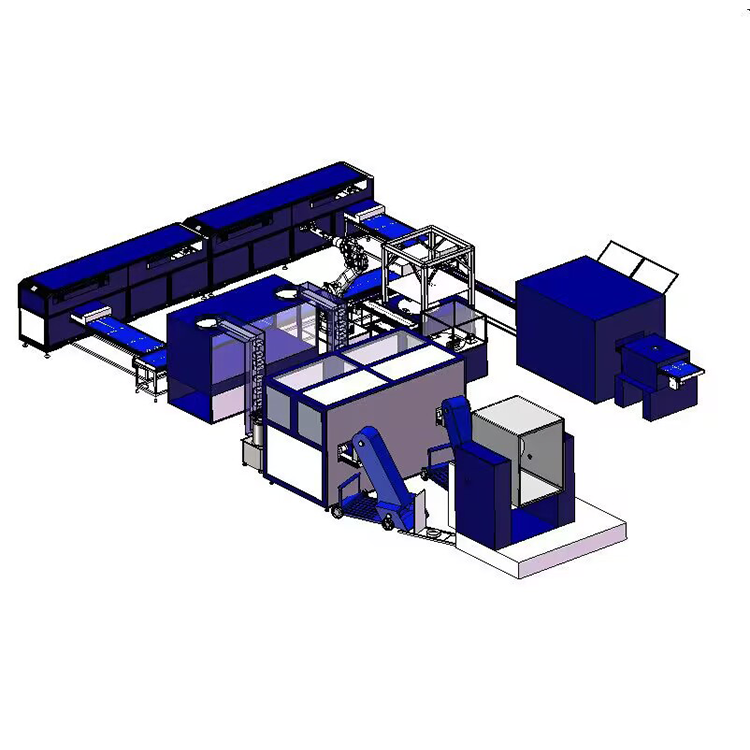

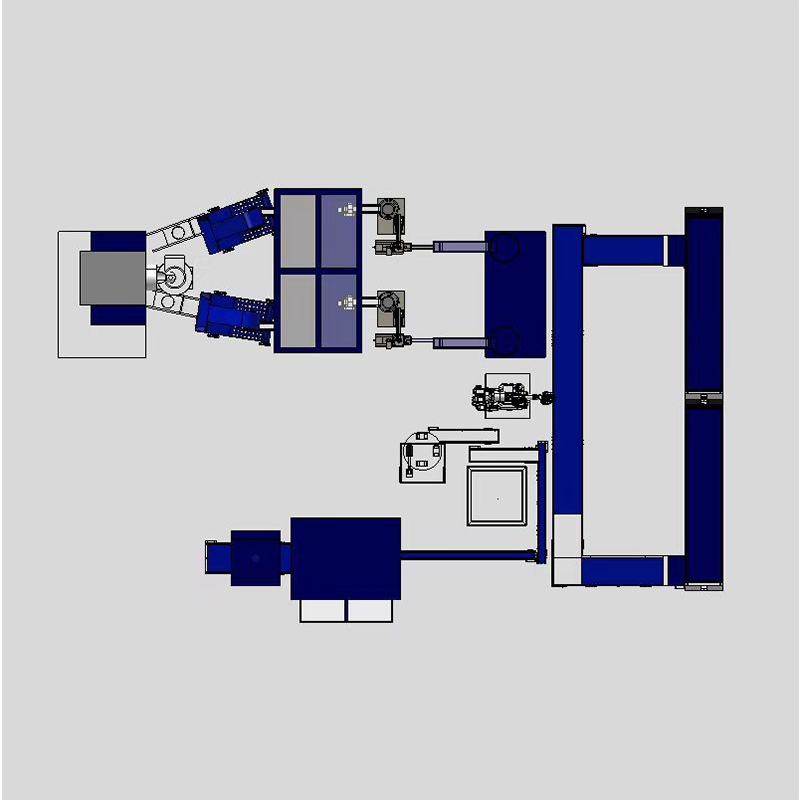

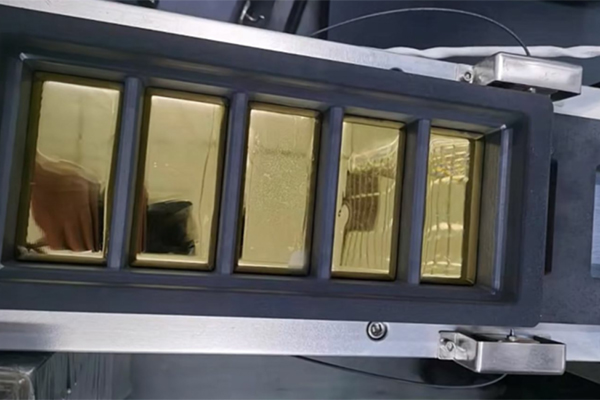

Tunnel Furnace Gold Vacuum Casting System

tlhahiso: 4 li-blocks / hora, boloko bo bong le bo bong bo boima ba 15kg;

Boholo ba mocheso oa ho sebetsa: 1350-1400 likhato tsa Celsius;

Mofuta oa khase e sireletsang: naetrojene; Tšebeliso ea moea: 5/H;

Mocheso oa metsi a kenang seboping le jenereithara: ho fihlela ho likhato tse 21 tsa Celsius;

Kakaretso ea tšebeliso ea metsi: 12-13 / H;

Khatello e hlokahalang ea metsi a pholileng: 3 ho 3,5 bar;

Phallo ea moea e hlokahalang bakeng sa moea: 0.1 m / s;

Khatello ea moea e hlokahalang ho tloha sebōping: 6 bar;

Mofuta oa Tlaleho le Karohano: Graphite 400 oz;

Kakaretso ea sebaka sa ho kenya sebōpi ke 18.2M2, bolelele ke 26500mm, 'me bophara ke 2800mm.

Node ea ho qhibiliha e laoloa ke libaka / libaka tsa mosebetsi tse latelang:

E entsoe ka tšepe e sa hloekang. Kopo: Ho paka likaroloana tsa khauta ka har'a maqephe a graphite. Ka sehloohong

likarolo: Motlakase push-step device displacement.

Sebaka sa ho kenya paramethara Sebelisa:

Thibela moea o kantle ho kena ka kotopong Mokhoa oa ho pholisa: metsi Likarolo tse kholo: partition ea mobile e nang le taolo ea moea, nozzle Kenya nitrogen.

Tšebeliso ea sebaka se qhibilihang:

e sebelisetsoang ho qhibilihisa likaroloana tsa khauta Sistimi ea ho pholisa: metsi Likarolo tsa mantlha: inductor e nang le samente ea refractory, infrared

Sensor ea mocheso, tsamaiso ea ho fana ka naetrojene

Sebaka sa ho pholisa:

karohano e nang le taolo ea moea, nozzle Kenya nitrogen. le vacuum.

Sebaka sa ho laolla:

E entsoe ka tšepe e sa hloekang. Morero:

Ntša sehlahisoa se felileng tlalehong.

Module oa Matla, Kakaretso ea Mojule: Matla a matla: 380v, 50Hz; Mehato ea 3 Matla a jenereithara:

60kW; tse ling ke 20KW. Kakaretso ea matla a hlokahalang: 80KW

Sebaka sa Taolo:

Sebaka sa ho sebetsa bakeng sa libopi tsohle

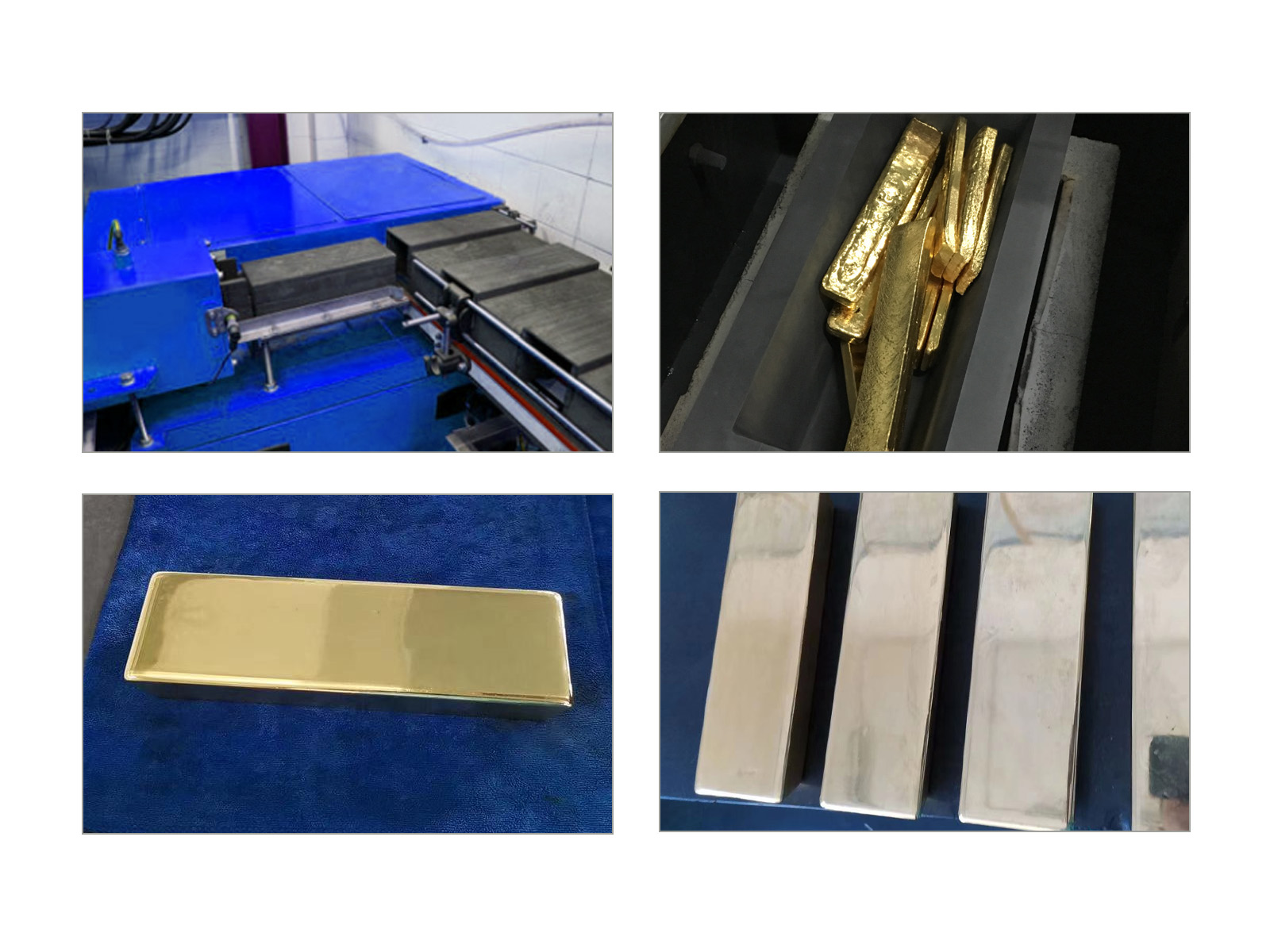

Pontšo ea Sehlahisoa

Mohala oa tlhahiso ea khauta ea kotopo o ikemetseng ke ofe?

Mohala oa tlhahiso ea khauta o ikatisang ka botlalo: ho fetola indasteri ea khauta

Indasteri ea khauta esale e le lets'oao la leruo le nala, 'me tlhoko ea litšepe tsa khauta e ntse e hola. Ha theknoloji e ntse e tsoela pele, tlhahiso ea litšepe tsa khauta e fetohile haholo. E 'ngoe ea lintlafatso tse ncha ka ho fetesisa indastering ke mohala oa tlhahiso ea khauta ea kotopo e ikemetseng ka botlalo. Theknoloji ena e tsoetseng pele e fetotse tsela eo mekoallo ea khauta e etsoang ka eona, ea ntlafatsa ts'ebetso, ho nepahala le boleng. Sengoliloeng sena, re tla hlahloba hore na mohala oa tlhahiso ea khauta ea kotopo o ikemetseng ka botlalo ke eng, o sebetsa joang, le phello ea ona indastering ea khauta.

Mohala oa tlhahiso ea khauta ea kotopo ka botlalo ke eng?

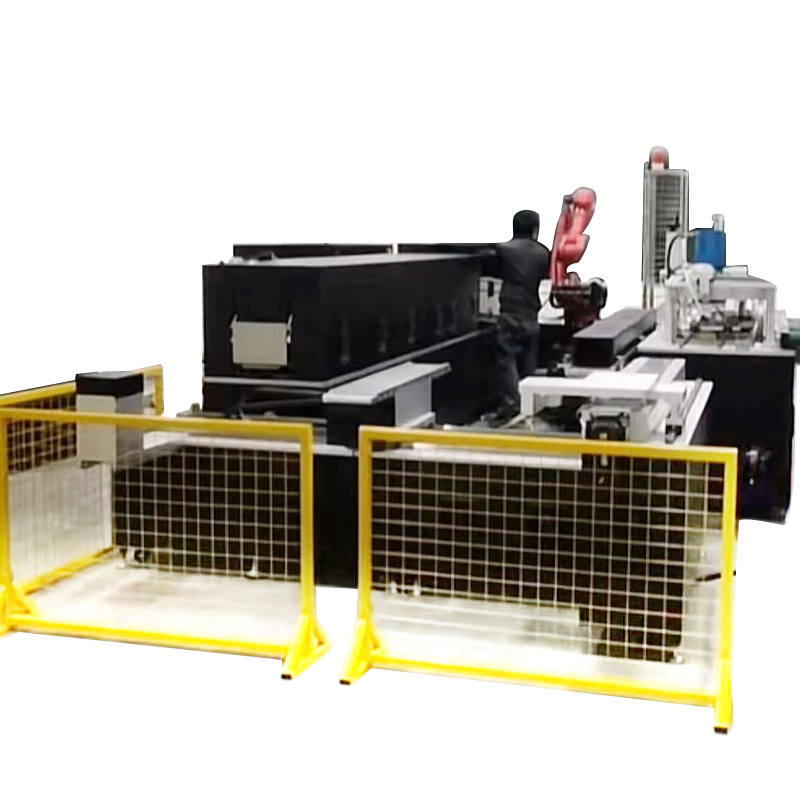

Mohala oa tlhahiso ea khauta ea kotopo ea othomathike ka botlalo ke sistimi e tsoetseng pele e etselitsoeng tlhahiso e ikemetseng ea khauta. E na le letoto la mechini e hokahantsoeng le lisebelisoa tse sebetsang hammoho ka mokhoa o ts'oanelang ho fetola thepa e tala hore e be maballo a khauta a felileng. Ts'ebetso eohle e etsoa ka botlalo ntle le ho kenella ka letsoho, ho fokotsa haholo kotsi ea phoso ea motho.

Karolo ea bohlokoa ea mola ke sebōpi sa kotopo, e leng sebōpi se etselitsoeng ka ho khetheha ho qhibilihisa le ho hloekisa khauta. Sebōpi se na le mokhoa o tsoetseng pele oa ho laola mocheso le li-sensor ho netefatsa hore mocheso o nepahetseng le o tsitsitseng oa thepa ea khauta. Ho phaella moo, mohala oa tlhahiso o kenyelletsa li-conveyors tse fapa-fapaneng, liforomo, mekhoa ea ho pholisa le mekhoa ea ho laola boleng ba ho tsamaisa mokhoa oohle oa tlhahiso.

The kotopo sebōpi khauta silevera bareng tlhahiso line e kenyeletsa

1. Metal granulator

2. Sieving ka tsamaiso ea vibration le tsamaiso ea ho omisa

3. Fetisetsa vacuum tsamaiso

4. Mokhoa oa ho noa

5. Sisteme ea ho lahla khauta ea kotopo

6. Ho hloekisa le ho bentša tsamaiso

7. Sistimi ea ho tšoaea matheba

8. Logo stamping

9. Ho paka tsamaiso

E sebetsa joang?

Mohala oa tlhahiso ea khauta ea kotopo o itirisang ka botlalo o sebetsa ka letoto la mekhahlelo e hokahaneng, e 'ngoe le e 'ngoe e etselitsoe ho etsa mosebetsi o itseng ts'ebetsong ea tlhahiso ea bareng ea khauta. Mokhoa ona o qala ka ho kenya thepa ea khauta e tala ka sebōping, moo e qhibilihang le ho hloekisoa ho tlosa litšila. Mocheso le nako ea ho futhumatsa li laoloa ka hloko ho finyella bohloeki bo lakatsehang le ho lumellana ha khauta e qhibilihisitsoeng.

Ka mor'a hore thepa ea khauta e hloekisoe, e tšeloa ka har'a liforomo ebe e bōptjoa hore e be sebopeho se batloang sa khauta. Mefuta e entsoe ka nepo ho hlahisa mekoallo ea khauta ea boholo le boima bo fapaneng ho fihlela litlhoko tse fapaneng tsa 'maraka. Ka mor'a hore khauta e tiee, e romeloa ka mokhoa oa ho pholisa ho tsitsisa sebopeho sa eona le mocheso.

Taolo ea boleng ke karolo ea bohlokoa ea mohala oa tlhahiso, ka mekhoa e tsoetseng pele ea tlhahlobo e kopantsoeng ho netefatsa hore mekoallo ea khauta e finyella litekanyetso tse phahameng ka ho fetisisa tsa bohloeki le boleng. Phapang efe kapa efe kapa bofokoli leha e le bofe bo khetholloa le ho rarolloa hang-hang, ho netefatsa hore ho hlahisoa litšepe tsa khauta tse phethahetseng feela.

Tšusumetso ho indasteri ea khauta

Kenyelletso ea mohala oa tlhahiso ea khauta ea kotopo o itirisang ka botlalo e bile le phello e matla indastering ea khauta. Theknoloji ena e tsoetseng pele e fetotse ts'ebetso ea tlhahiso, e fana ka melemo e mengata ea bohlokoa e fetolang indasteri.

Ntlha ea pele, ho iketsetsa mekhoa ea tlhahiso ho eketsa katleho le tlhahiso haholo. Ka ho kenella ho fokolang ka letsoho, mohala o ka sebetsa ka ho tsoelang pele, oa eketsa tlhahiso le ho fokotsa nako ea tlhahiso. Sena se lumella bahloekisi ba khauta le bahlahisi ho fihlela tlhoko e ntseng e eketseha ea litšepe tsa khauta ka katleho le ka bokhabane.

Ho feta moo, ho nepahala le ho tsitsana ho fihletsoeng ka boiketsetso ho ntlafatsa boleng ba mekoallo ea khauta e hlahisoang. Mekhoa e tsoetseng pele ea ho laola mocheso le mekhoa ea tlhahlobo ea boleng e netefatsa hore mekoallo ea khauta e finyella litekanyetso tse phahameng ka ho fetisisa tsa bohloeki, e kenyang tšepo ho bareki le ho batseteli.

Ntle le moo, mohala oa tlhahiso ea khauta o ikatisang ka botlalo o ntlafatsa polokeho le ho fokotsa tšusumetso ea tikoloho ea tlhahiso ea bareng ea khauta. Ka ho fokotsa ho kenya letsoho ha batho ts'ebetsong ea tlhahiso, kotsi ea likotsi le likotsi li fokotsehile haholo. Ho feta moo, ts'ebeliso e nepahetseng ea matla le lisebelisoa mehala ea tlhahiso ea boiketsetso e kenya letsoho molemong oa mokhoa o tsitsitseng le o se nang tikoloho oa tlhahiso ea khauta.

Ho feta moo, ho amoheloa ha theknoloji ena e tsoetseng pele ho etsa hore baetsi ba khauta ba be le tlholisano 'marakeng oa lefatše. Bokhoni ba ho hlahisa liballo tsa khauta tsa boleng bo holimo ka lebelo le potlakileng ho li fa monyetla oa leano, ho li lumella ho fihlela litlhoko tsa bareki ba machabeng le ho atolosa phihlello ea bona ea mebaraka.

Ka bokhuts'oane, mohala oa tlhahiso ea khauta o ikemetseng oa tonnel o emela tsoelopele e kholo indastering ea khauta. Mekhoa ea eona ea ho iketsetsa le e nepahetseng e ntlafatsa ts'ebetso, boleng le tlhōlisano ea tlhahiso ea khauta. Ha tlhoko ea khauta e ntse e eketseha, theknoloji ena e ncha e tla bapala karolo ea bohlokoa ho khotsofatsa tlhoko ea 'maraka le ho theha bokamoso ba indasteri ea khauta.

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur