KHOPO KHOPO

TSEBO MOTHEO SHEBA

Wire Bonding ke Eng?

Wire bonding ke mokhoa oo ka oona bolelele ba terata e nyenyane ea tšepe e nang le bophara bo fokolang e khomaretsoeng holim'a tšepe e lumellanang ntle le tšebeliso ea solder, flux, 'me maemong a mang ka tšebeliso ea mocheso o ka holimo ho likhato tse 150 tsa Celsius.Lisebelisoa tse bonolo li kenyelletsa Khauta (Au), Copper (Cu), Silver (Ag), Aluminium (Al) le li-alloys tse kang Palladium-Silver (PdAg) le tse ling.

Ho Utloisisa Mekhoa le Mekhoa ea ho Tlamahanngoa ha Wire bakeng sa Likopo tsa Kopano ea Micro Electronics.

Mekhoa ea ho kopanya Wedge / Mekhoa: Ribone, Thermosonic Ball & Ultrasonic Wedge Bond

Khokahano ea mohala ke mokhoa oa ho etsa likhokahano lipakeng tsa potoloho e kopaneng (IC) kapa sesebelisoa se tšoanang sa semiconductor le sephutheloana sa eona kapa leadframe nakong ea tlhahiso.E boetse e sebelisoa ka tloaelo hona joale ho fana ka likhokahano tsa motlakase likopanong tsa pakete ea betri ea Lithium-ion. Ka kakaretso ho kopanngoa ha terata ho nkoa e le e theko e boima ka ho fetisisa le e feto-fetohang ea theknoloji e fumanehang ea microelectronic interconnect, 'me e sebelisoa boholo ba liphutheloana tsa semiconductor tse hlahisoang kajeno. Ho na le mekhoa e 'maloa ea ho kopanya mohala, e kenyelletsang: Thermo-Compression Wire Bonding:

Thermo-compression wire bonding (e kopantseng le libaka tse ka bang teng (hangata Au) hammoho ka tlas'a matla a ho tiisa a nang le mocheso o phahameng oa sehokelo, hangata o fetang 300 ° C, ho hlahisa weld), qalong e ile ea ntlafatsoa lilemong tsa bo-1950 bakeng sa likhokahano tsa li-microelectronics, leha ho le joalo. ka potlako e ile ea nkeloa sebaka ke Ultrasonic & Thermosonic bonding lilemong tsa bo-60 e le theknoloji e ka sehloohong ea ho hokahanya.Thermo-compression bonding e ntse e sebelisoa bakeng sa lits'ebetso tsa niche kajeno, empa hangata e qojoa ke bahlahisi ka lebaka la mocheso o phahameng (hangata o senyang) o hlokahalang bakeng sa ho etsa bond e atlehileng.Ultrasonic Wedge Wire Bonding:

Lilemong tsa bo-1960, Ultrasonic wedge wire bonding e ile ea fetoha mokhoa o ka sehloohong oa ho hokahanya.Tšebeliso ea ho sisinyeha ha maqhubu a phahameng (ka transducer e hlabang) ho sesebelisoa sa ho kopanya se nang le matla a nako e le 'ngoe, se lumelletse lithapo tsa Aluminium le Khauta hore li chesetsoe mocheso oa kamore.Tlhahiso ena ea Ultrasonic e thusa ho tlosa litšila (li-oxides, litšila, joalo-joalo) ho tloha libakeng tse tlamahano qalong ea potoloho ea ho kopanya, le ho khothalletsa kholo ea intermetallic ho tsoela pele ho ntshetsa pele le ho matlafatsa tlamo.Maqhubu a tloaelehileng a ho bonta ke 60 – 120 KHz. Thekniki ea ultrasonic wedge e na le mekhoa e 'meli ea bohlokoa ea ho kopanya terata: terata e kholo (e boima) bakeng sa >100µm lithapo tse nang le bophara ba 100µm tse ntle (tse nyane) bakeng sa <75µm diameter wiresMehlala ea tloaelo ea Ultrasonic bonding e fumanoa mona bakeng sa terata e ntle le mona bakeng sa terata e kholo.Ultrasonic wedge terata bonding e sebelisa sesebelisoa se itseng sa ho tlama kapa "wedge," hangata e hahiloeng ho tloha Tungsten Carbide (bakeng sa terata ea Aluminium) kapa Titanium Carbide (bakeng sa terata ea Khauta) ho latela litlhoko tsa ts'ebetso le bophara ba terata;li-wedges tsa ceramic tse etselitsoeng lisebelisoa tse ikhethang le tsona lia fumaneha.Thermosonic Wire Bonding:

Moo ho hlokehang ho futhumala ha tlatsetso (haholo-holo bakeng sa terata ea Khauta, e nang le likhokahano tsa li-bonding tsa 100 - 250 ° C), mokhoa ona o bitsoa Thermosonic wire bonding.Sena se na le melemo e meholo ho feta mokhoa o tloaelehileng oa thermo-compression system, kaha ho hlokahala hore ho be le lithempereichara tse tlase haholo (Au bonding mocheso oa kamore e boletsoe empa ka ts'ebetso ha e tšepahale ntle le mocheso o eketsehileng). Thermosonic Ball Bonding:

Mofuta o mong oa ho kopanya mohala oa Thermosonic ke Ball Bonding (sheba potoloho ea bolo mona).Mokhoa ona o sebelisa sesebelisoa sa ceramic capillary bonding holim'a meralo e tloaelehileng ea wedge ho kopanya litšoaneleho tse ntle ka ho fetisisa ho thermo-compression le ultrasonic bonding ntle le mathata.Thermosonic vibration e etsa bonnete ba hore mocheso oa mocheso o lula o le tlaase, ha motsoako oa pele, bolo e hatelitsoeng ka thermally e lumella hore mohala le bond ea bobeli e behoe ka tsela leha e le efe, eseng ka tsela e lumellanang le bond ea pele, e leng tšitiso ho Ultrasonic wire bonding. .Bakeng sa ho iketsetsa molumo o phahameng, li-bonders tsa bolo li potlakile haholo ho feta li-bonder tsa Ultrasonic / Thermosonic (Wedge), e leng se etsang hore bolo ea Thermosonic e tlamahane theknoloji e ka sehloohong ea khokahanyo ea microelectronics lilemong tse 50+ tse fetileng.

Khokahano ea ribone, e sebelisang litheipi tsa tšepe tse bataletseng, esale e le eona ntho e ka sehloohong ho lisebelisoa tsa elektroniki tsa RF le Microwave ka lilemo tse mashome (ribone e fana ka ntlafatso e kholo tahlehelong ea matšoao [phello ea letlalo] khahlano le terata e chitja ea setso).Liribone tse nyane tsa Khauta, tse bophara ba 75µm le botenya ba 25µm, li kopanngoa ka mokhoa oa Thermosonic ka sesebelisoa se seholo sa sefahleho se bataletseng. tlhokahalo ea loop e tlase, likhokahano tse phahameng tsa density li eketsehile.

Gold bonding terata ke eng?

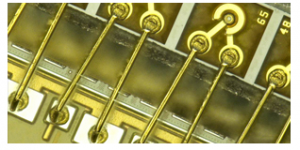

Ho kopanya terata ea khauta ke mokhoa oo ka oona terata ea khauta e hokeloang lintlheng tse peli kopanong ho etsa khokahano kapa tsela e tsamaisang motlakase.Mocheso, li-ultrasonics, le matla li sebelisoa kaofela ho theha lintlha tse khomaretsoeng bakeng sa mohala oa khauta. Mokhoa oa ho theha ntlha ea ho khomarela e qala ka ho thehoa ha bolo ea khauta ntlheng ea sesebelisoa sa wire bond, capillary.Bolo ena e hatelloa holim'a kopano e futhumetseng ha e ntse e sebelisa matla a mabeli a khethehileng a kopo le maqhubu a 60kHz - 152kHz ea ultrasonic motion with the tool. Hang ha tlamo ea pele e entsoe, terata e tla sebelisoa ka thata ka thata. mokhoa oa ho theha sebopeho se loketseng sa loop bakeng sa geometry ea kopano.Tlamo ea bobeli, eo hangata e bitsoang stitch, e thehoa holim'a sebaka se seng ka ho hatella ka terata le ho sebelisa clamp ho tabola terata ka bond.

Ho kopanya terata ea khauta ho fana ka mokhoa oa khokahano ka har'a liphutheloana tse nang le motlakase o mongata, o batlang o lekana le boholo ho feta li-solders tse ling.Ho feta moo, lithapo tsa khauta li na le mamello e phahameng ea oxidation ha li bapisoa le lisebelisoa tse ling tsa terata 'me li bonolo ho feta tse ngata, tse bohlokoa bakeng sa libaka tse hlokolosi.

Ts'ebetso e ka boela ea fapana ho latela litlhoko tsa kopano.Ka lisebelisoa tse hlokolosi, bolo ea khauta e ka behoa sebakeng sa bobeli sa tlamahano ho theha maqhama a matla le "bonolo" ho thibela tšenyo e ka holim'a karolo.Ka libaka tse thata, bolo e le 'ngoe e ka sebelisoa e le qalo ea li-bond tse peli, ho etsa tlamo e bōpehileng "V".Ha khoele ea terata e hloka ho ba matla haholoanyane, bolo e ka behoa ka holim'a sekoti ho etsa tlamo ea tšireletso, ho eketsa botsitso le matla a terata.Likopo tse ngata tse fapaneng le liphapang tsa ho kopanya lithapo li batla li se na moeli 'me li ka finyelloa ka ho sebelisa software e ikemetseng ho litsamaiso tsa terata tsa Palomar.

Ntlafatso ea li-wire bonding:

Khokahano ea mohala e ile ea sibolloa Jeremane lilemong tsa bo-1950 ka tekolo ea mahlahahlaha, 'me ka mor'a moo e entsoe mokhoa o laoloang haholo.Kajeno e sebelisoa haholo bakeng sa li-chips tsa semiconductor tse hokahanyang motlakase ho paka li-lead, lihlooho tsa disk drive ho li-amplifiers, le lits'ebetso tse ling tse ngata tse lumellang hore lintho tsa letsatsi le letsatsi li be nyane, "tse bohlale", 'me li sebetse hantle.

Bonding Wires Applications

Ho ba le phello e ntseng e eketseha ea miniaturization ho lisebelisoa tsa elektroniki

ka lithapo tse tlamang ho fetoha likarolo tsa bohlokoa tsa

likopano tsa elektronike.

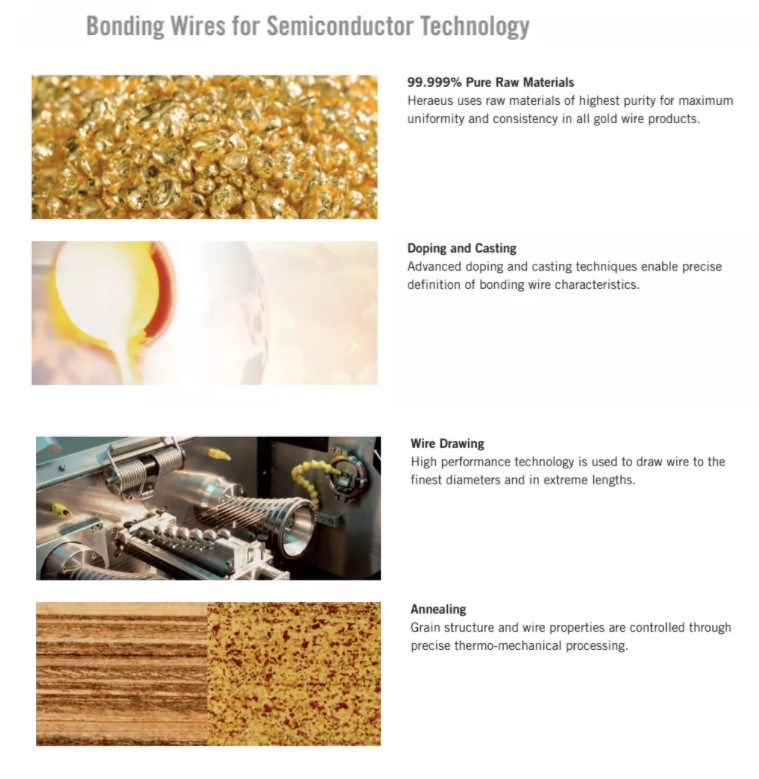

Bakeng sa morero ona mehala e metle le ea ultrafine bonding ea

ho sebelisoa khauta, aluminium, koporo le palladium.Phahameng ka ho fetisisa

litlhoko li etsoa boleng ba tsona, haholo-holo mabapi le

ho ts'oana ha thepa ea terata.

Ho itšetlehile ka sebopeho sa bona sa lik'hemik'hale le tse khethehileng

thepa, lithapo bonding li ikamahanya le maemo ho tlamahano

mokhoa khetha le ho jarolla ka ho iketsa bonding mechine e le

hammoho le mathata a fapaneng a theknoloji ea kopano.

Heraeus Electronics e fana ka mefuta e mengata ea lihlahisoa

bakeng sa lisebelisoa tse fapaneng tsa ho

Indasteri ea likoloi

Mehala ea puisano

Baetsi ba semiconductor

Indasteri ea thepa ea bareki

Lihlopha tsa lihlahisoa tsa Heraeus Bonding Wire ke:

Lithapo tsa bonding bakeng sa lits'ebetso ka polasetiki e tlatsitsoeng

likarolo tsa elektronike

Aluminium le aluminium alloy bonding wires bakeng sa

lisebelisoa tse hlokang mocheso o tlase oa ts'ebetso

Copper bonding lithapo e le botekgeniki le

mefuta e meng ea moruo ho feta mehala ea khauta

Liribone tsa tšepe tsa bohlokoa le tse seng tsa bohlokoa bakeng sa

dikgokelo tsa motlakase tse nang le dibaka tse kgolo tsa kgokahanyo.

Bonding Wires Production Line

Nako ea poso: Jul-22-2022